9

Routine cleaning

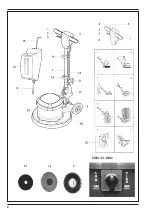

For routine cleaning, your machine is equipped with the

following accessories:

- Spraymaster, drive plate for pads, yellow-and-

brown or green pad for Low-Speed or Spraymaster,

drive plate for pads, red pad for High Speed

Fill the spray can with the desired product.

Fit the drive plate with the desired pad.

Start the machine.

When you pull the Spraymaster lever a few times the

cleaning agent is sprayed onto the floor. Now start

cleaning immediately until a shine is produced.

We advise cleaning the surface in relatively small areas

at a time. The machine is ideal for cleaning with

polymer dispersions. The coatingʼs resistance to

foot traffic and general wear and tear is preserved.

Streaks and marks are easier to remove.

Polishing

For polishing, equip your machine with the following

accessories:

- Drive plate for pads, white pad.

Fit the drive plate with the pad.

Then start the machine.

Service

For repairs, please contact your specialist wholesaler or

one of the service shops.

You will be expertly and quickly served.

Warning!

This machine is only intended for use on

level surfaces with a maximum gradient of up to 2 %.

Warning!

This machine is not approved for use on

public paths and roads.

Servicing instructions

the following instructions must always be

observed

When cleaning and servicing the machine, replacing

parts or when changing over to a different function,

switch off the drive and remove the plug.

The power supply lead must not be damaged by driving

over it, crushing, tugging etc.

Check the power supply lead regularly for signs of

damage.

The machine must not be used if the power supply lead

is not in perfect condition.

When using or replacing the power supply or

equipment supply leads, use only those specified by

the manufacturer.

When replacing the plug-and-socket connectors of

power supply or equipment supply leads, splash

protection and mechanical strength must be

assured.

When transporting the machine in lifts, put the shaft/

bar in a vertical position so that it cannot catch on

the lift walls.

The shaft/bar is automatically secured against recoil by

the patented shaft/bar adjustment unit.

Only the spray and cleaning agents suitable for the

machineʼs purpose may be used.

Never use highly flammable, combustible, toxic, health-

hazardous, corrosive or irritant substances.

Repairs, including the fitting of spray agent lines

and hoses, may only be carried out by approved

customer service shops or by specialists in this

field who are familiar with all the relevant safety

regulations.

Storage

When the machine is not being used, store it in a dry

place and in normal room conditions (not below under

0°C).

Technical specifications

SD 43-165

SD 43-400

SDM 43-180

SDM 43-450

SDM 43-DUO

SDM 43-900/1500

SDM 53-1500

A.C. motor

230/50

230/50

230/50

230/50

230/50

230/50

230/50

Rated power

1000

1100

1200

1500

1200-1500

1800

1800

5,6

5,7

5,2

6,5

5,2/8,1

7,2

7,2

Brush (rpm)

165

400

180

450

190/380

900/1500

1500

Brush (mm)

430

430

430

430

430

430

530

Working height (mm)

250

250

330

330

330

130/320

130/320

Working weight (kg)

30

31

36

40

40

44

46

Protection class

I/IPx4

I/IPx0

I/IPx4

I/IPx0

I/IPx4

I/IPx0

I/IPx0

Belt-driven

X

X

X

X

X

X

X

Handle vibration level m/s2

1,05

1,05

1,05

1,05

1,05

1,05

1,05