FORM NO. 56041423 / SD 4317, SD 5120 - 6

AFTER USE

1

Unplug the Power Cord, coil it and hang it from the Operator Handle

Grips.

2

Remove the pad holder or brush from the machine. Clean the pad or

brush and hang it up to dry. Allow buffing pads to dry completely

before using again.

3

Store brushes and pad holders separate from the machine. Never

store the machine with the pad holder or brush on the machine.

4

Wipe the entire machine with a clean, damp cloth. Wipe the under-

side of the brush housing after wet use.

5

Inspect the entire machine and all accessories for damage. Perform

any required maintenance or repairs before storage.

6

Store the machine in a clean, dry place with the Handle locked in the

upright position.

TROUBLESHOOTING

SWIRLS ON THE FLOOR AFTER SCRUBBING

•

Floor not clean.

•

Incorrect solution.

•

Area not properly swept - debris in pad or brush.

•

Improper pad or brush for the job.

•

Moving the machine too fast.

SWIRLS ON THE FLOOR AFTER DRY BUFFING

•

Moving the machine too fast.

•

Floor finish too soft.

•

Area not properly swept - debris in pad or brush.

•

Improper pad or brush for the job.

CIRCLES ON THE FLOOR

•

Machine standing still while the brush or pad is running.

FLOOR FINISH REMOVED

•

Improper pad... too aggressive.

•

Solution too strong.

MACHINE WOBBLES DURING OPERATION

•

Defective pad... one side is more dense than the other.

•

Machine left sitting on brush or pad for extended period of time

causing bristles or pad to “take a set”.

•

Pad not “seated” properly into pad holder bristles.

•

Warped block on brush or padholder - replace.

MACHINE DOES NOT RUN

•

Check plug for proper connection - on machine and at wall outlet.

•

Check building circuit breaker.

•

Call for service.

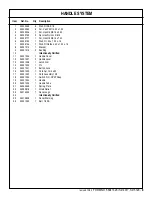

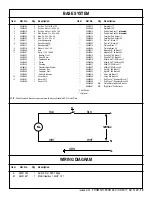

TECHNICAL SPECIFICATIONS (as installed and tested on the unit)

Model

SD 4317

SD 5120

Model Number

56201631

56201632

Motor

1.50 hp, 120V

1.50 hp, 120V

Transmission

Triple-Planetary

Triple-Planetary

Pad/Brush Speed

175 rpm

175 rpm

Pad/Brush Size

17” (43 cm)

20” (51 cm)

Wheels

5” (15 cm)

5” (15 cm)

Cord Length

50’ (15 m)

50’ (15 m)

Base Width

18” (46 cm)

20.75” (53 cm)

Height w/Handle

47” (120 cm)

47” (120 cm)

Net Weight (w/pad holder)

111 lbs (50.34 kg)

115 lbs (52.16 kg)

Shipping Weight (w/pad holder)

115 lbs (52.16 kg)

119 lbs (53.97 kg)

Construction:

Handle Tube

Extruded Aluminum

Extruded Aluminum

Upper Handle

Injection Molded Polypropylene

Injection Molded Polypropylene

Base

Roto Molded Polyethylene

Roto Molded Polyethylene

revised 9/99