S31NUK5120(3)2001-04

1

4

2

3

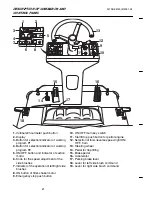

To collect light and bulky debris lift the front flap

using the left pedal (do not press the pedal down

for a long time, not to reduce the suction

capability of the machine).

The machine gets an automatic breaking

function when the accelerator pedal is released;

when necessary the service brake can also be

used (see the figure).

When driving in reverse gear an intermittent

acoustic signal will be heard and all the functions

will remain active.

The figure shows the functions of the command

lever:

1

- forward gear

2

- reverse gear

3

- horn

4

- front light On/Off.

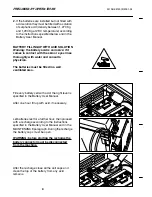

The machine is equipped with an emergency

stop button; by pressing this button (red light On)

a sudden stop of the machine will occur and all

functions will turn off, the petrol engine too.

To restart the machine turn the red button

clockwise (according to the arrow shown on the

button itself).

To restart the normal operation re-select one of

the two working programs

P1

or

P2

.

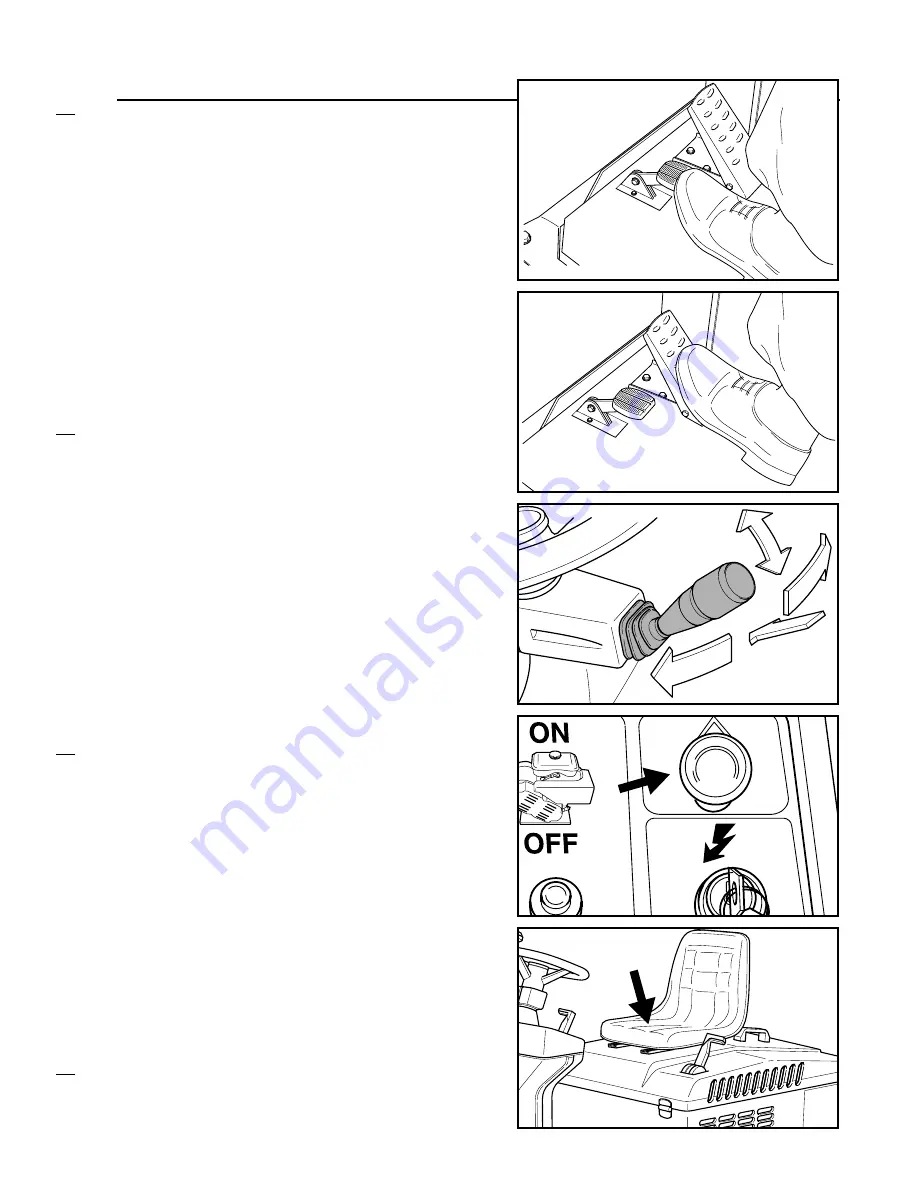

A safety device is located inside the operator

seat: the drive function - either forward or

reverse - is disabled as soon as the operator will

stand up or leave the seat.

USE

11