147

9

MOTOR

152T059

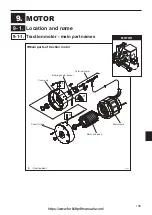

Sand paper

Brush

Commutator

l

Repairing surface of brush

l

If the contacting surface is not good, repair it as

follows.

152T042

l

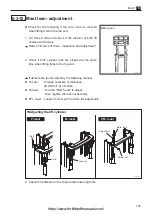

Inspection of contacting

surface of brush

Good

Not Good Not Good

Commutator

Brush

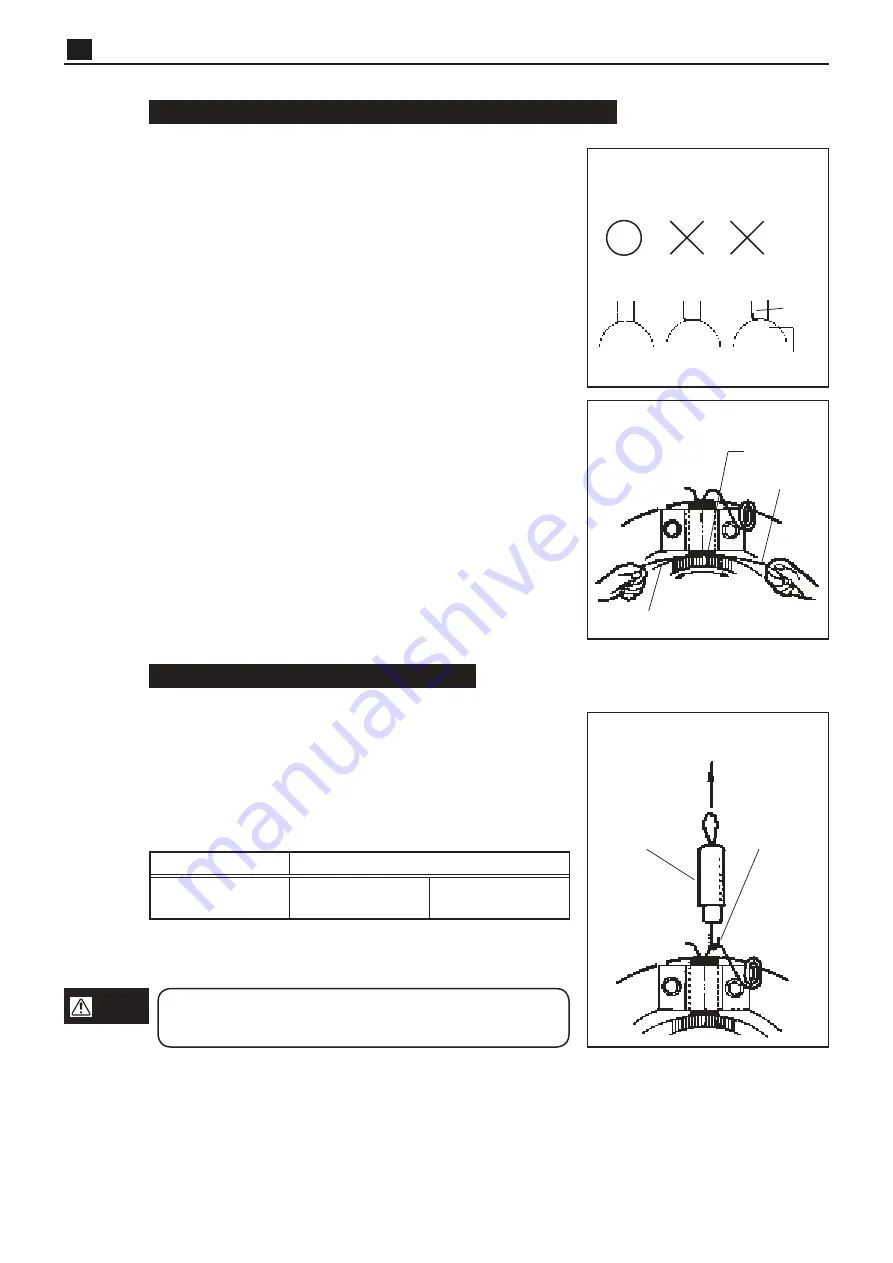

Inspection of force of spring

4

3

Inspection of contacting surface of brush

4

2

<Repairing procedure>

1. Insert a sand paper [#400] between COMMUTATOR

and BRUSH.

(Face the file side to the brush.)

2. Polish the contacting surface of the brush by moving a

sand paper or rotating COMMUTATOR by hand.

3. Blow the dust out with compressed air after repairing.

l

Hook a spring scale to the brush SPRING and check if

both springs have the same tension.

Then make sure of equal force on 2 springs.

<Specific force of SPRING>

Applicable motor

Reference value

EPS motor

(NIKKO only)

5 N

(0.5 kgf)

If the SPRING and/or the brush holder were

rusted, replace them.

CAUTION

152T060

Spring

l

Inspection of force of spring

Spring scale

https://www.forkliftpdfmanuals.com/