12

Using liquid packing

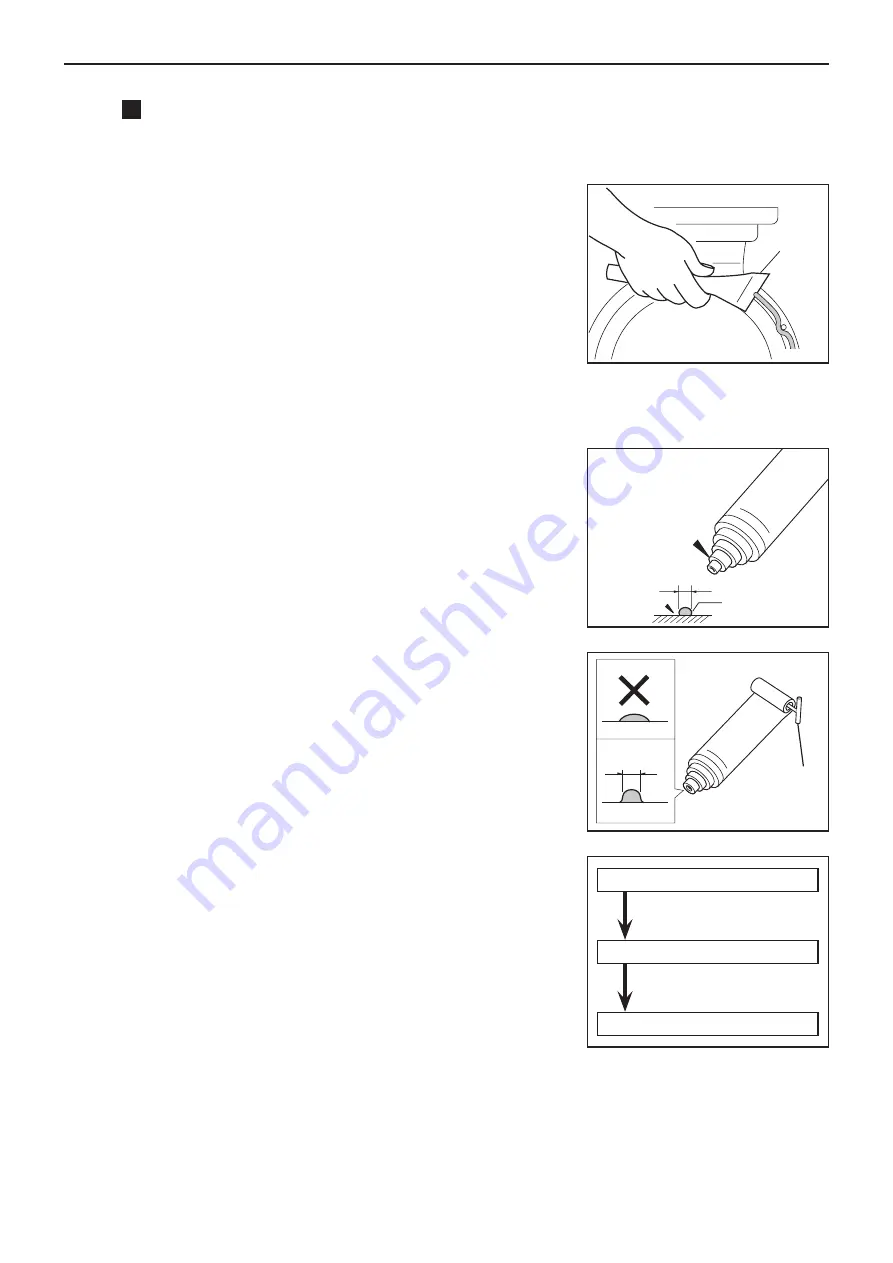

Applying liquid packing

l

152E105

152E106

152E107

Scraper

Liquid packing

3 -3.5 mm

Good

Apply liquid packing

Within 15 minutes

Wait for 30 minutes or more

Assembly

Filling oil/Operation

Not Good

Key to evacuate

liquid packing

3 - 3.5 mm

Mating surface

Cut the nozzle at the

second section

Remove the sealer adhered on the mating surface of the

casing by using a scraper or equivalent tool. Be careful

not to make scratches of 0.3 mm or deeper. If scratches

are made, repair the area by using an oil stone.

Wipe off the mating surfaces using a cloth soaked in

gasoline to remove oil and contamination.

* Do not use kerosene, light oil, or crude oil.

1.

Cut the nozzle of the liquid packing tube at about the

second section so that the bead width will be 3 to 3.5

mm.

2.

Attach a key for rolling up the tube, and apply the liquid

packing to the mating surface while rolling up the tube.

* Do not smooth out the bead; doing so may cause

leakage.

* When applying the liquid packing to bolt holes, apply it

on the internal portion of the mating surface.

3.

Close the mating surfaces within 15 minutes after the

liquid packing is applied.

4.

When tightening the bolts, always tighten temporarily

first, and then tighten them gradually, moving from one to

the next in a diagonal pattern.

5.

Wait for more than 30 minutes before adding oil or

operating the machine.

* Failure to do so may cause oil leakage.

6.

Scraping before application of seal

l

https://www.forkliftpdfmanuals.com/