70

BRAKE

6

212E053

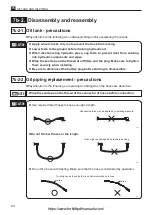

Teeth

l

Inspection of adjustor ass'y

2210056

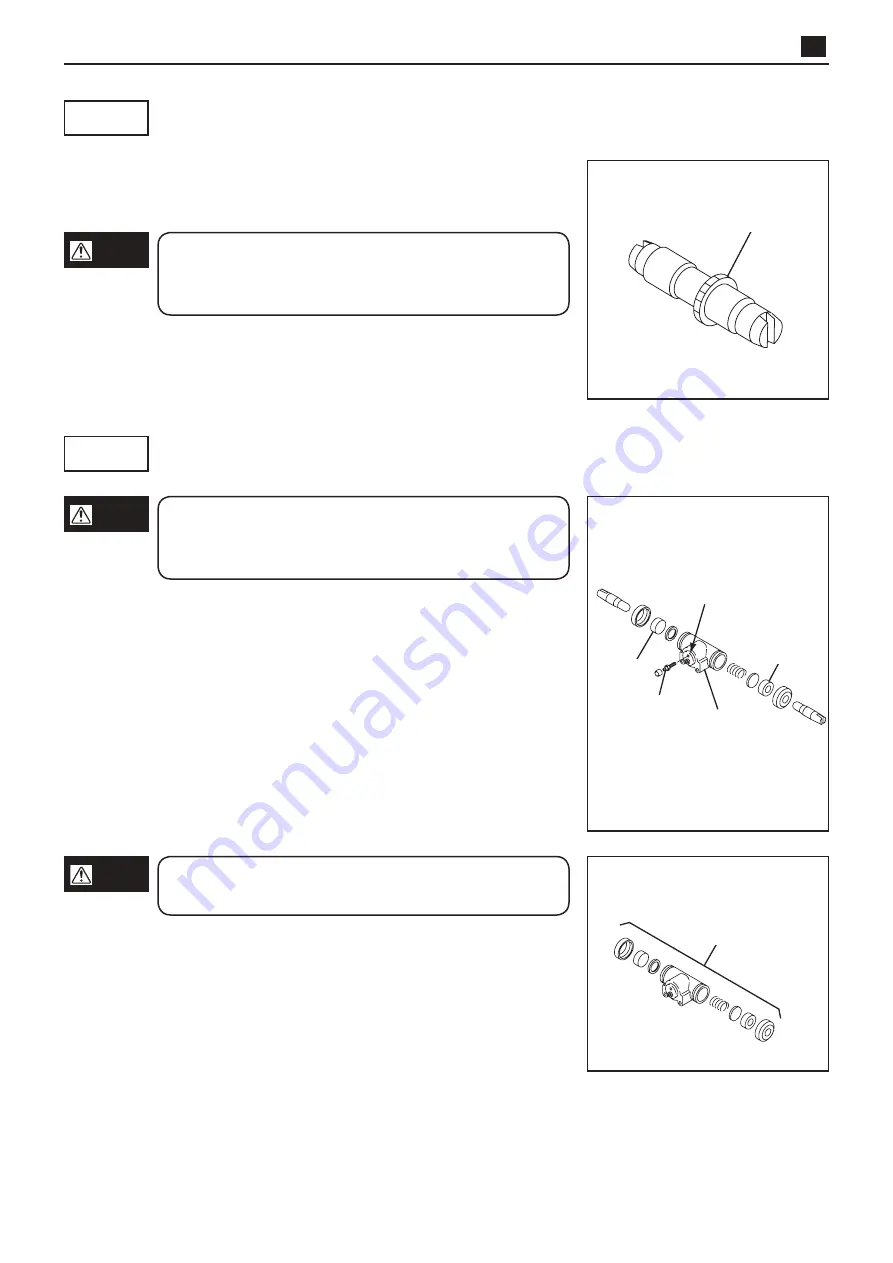

Piston

Cylinder body

Breather screw

Piston

Fitting surface of the

breather screw

l

Inspection of wheel cylinder

ass'y

1. Check the inside of the "Cylinder body" and the fitting

surface of the breather screw for damage or rust.

2. Check for damage and deterioration on the inner parts.

1. Check the teeth of the adjustor ass'y for wear and

deformation.

2210142

l

Replacing the cylinder kit

Cylinder kit

6-3-3. Adjustor ass'y - inspection and replacement

CAUTION

When the adjustor ass'y can not be turned

by hand or resistance is felt when turning it,

replace it with a new one.

6-3-4. Wheel cylinder ass'y - inspection and replacement

CAUTION

Before performing this inspection, clean the part

with a volatile cleaning grease, and then use

pressurized air to completely remove the grease.

Replace the cylinder kit at every

disassembling or annually.

CAUTION

https://www.forkliftpdfmanuals.com/