83

7b

OIL TANK AND OIL PIPING

Disassembly and reasembly

7b- 2.

l

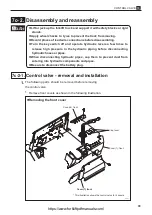

Pay attention to the following when disassembling and/or assembling the oil tank.

l

Pay attention to the following on replacing and fitting when the hoses are abnormal.

7b-2-1. Oil tank - precautions

NOTE

Wrap the seal tape on the thread of the connector of hoses before connection.

CAUTION

l

Apply wheel chocks to tyres to prevent the truck from moving.

l

Lower forks to the ground before draining hydraulic oil.

l

When disconnecting hydraulic pipes, cap them to prevent dust from entering

into hydraulic components and pipes.

l

Wrap the seal tape on the thread of oil filters and the plug. Make sure to tighten

them securely when installing.

l

Be sure to disconnect the battery plug before starting to disassemble.

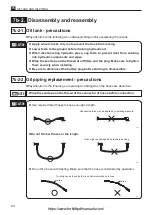

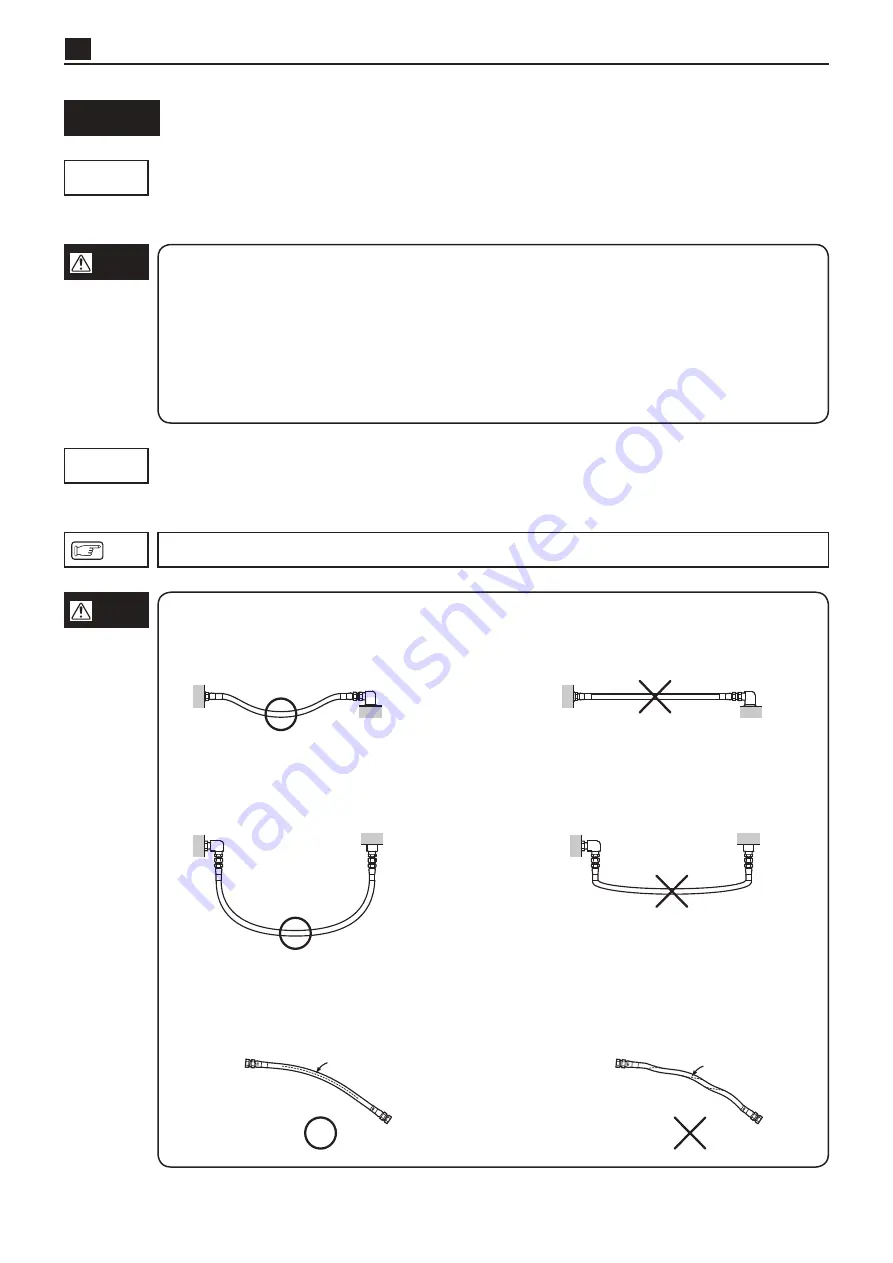

7b-2-2. Oil piping replacement - precautions

l

Use required rated hoses to keep enough strength.

152E125

l

Do not fit a hose with twisting. Make sure that the hose is not twisted by operation.

152E126

Letters

Letters

152E127

Twisting can be found by the line of letters marked on a hose.

Hose might be damaged due to sharp bending.

l

Do not fit short hoses in the length.

Unexpected force may be applied by operating pressure.

CAUTION

https://www.forkliftpdfmanuals.com/