26

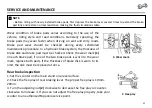

2: Drain plug, 3: Seal

4: Oil spring, 5: Oil screen

1: Drain bolt

SERVICE AND MAINTENANCE

1. First put an empty container under the engine crankcase.

2. Remove the drain bolt

(1)

at the left side of the crankcase.

3. Remove the drain plug

(2)

at the right side of the crankcase. The oil spring

(4)

will fall out.

3. Depress the kick starter several times to drain the oil completely.

4. Retrieve the oil screen

(5)

and clean it.

5. Inspect the drain plug, seal, oil spring and oil screen and confirm that they are in good condition.

Then re-assemble them as shown and tighten the drain plug

(2)

.

6. Tighten the drain bolt

(1)

.

7. Remove the oil plug

(7)

.

1

6: Oil filling port

7: Oil plug

2