DW1401989 Rev.K2

Dec 18, 2019

2

Compatibility Requirement

To ensure proper operation, the module shall be connected to UL listed

control panel NFU-7000 series.

Before Installing

Disconnect power to the control panel before installing the module. If the

module is installed in an existing operational system, inform the operators

and local authorities that the system will be temporarily out of service.

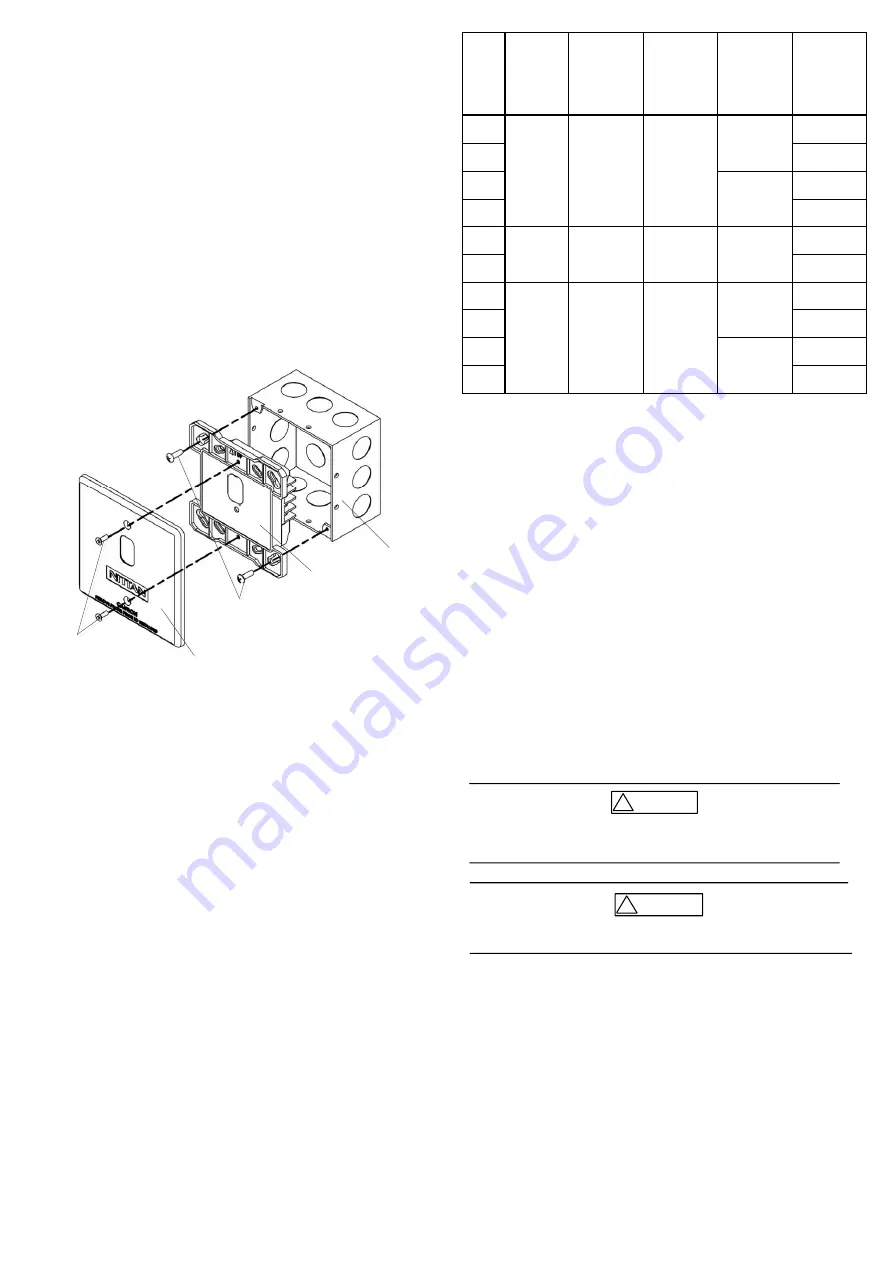

Mounting

Mount the module directly to 4’’ square electrical box (UL Listed).

Secure the module to the electrical box, as shown in Figure 3.

Main unit

Outer cover EVA

Electrical box

Tapping screw

Pan head screw

Figure 3

Setting

・

Address Setting

Use EVA-AD2 Programmer for setting the address of the module prior to

installation. EVA-DIP-SCI has an address given at random from factory.

Connect the Programmer with the address setting port to change the

address to any of 1-254 (dec), with reference to the instruction manual of

EVA-AD2 Programmer. The address can be set regardless of whether

power supply from the control panel is turned on or off. During setting

address, the module does not respond to the control panel.

Set the address of module according to Job data.

・

Subtype Setting

Set the subtype depending on the wiring configuration as below. The

subtype is to be set through the Configurator for the control panel.

Sub

Type

Input

Method

Open

-

circuit

Detection

Short

-

circuit

Detection

Class

Interrupt

1

Normally

Open

Yes

No

Class B

Disabled

2

Enabled

3

Class A

Disabled

4

Enabled

5

Normally

Close

No

Yes

Class B

Disabled

6

Enabled

7

Normally

Open

Yes

Yes

Class B

Disabled

8

Enabled

9

Class A

Disabled

10

Enabled

When interrupt is enabled, it allows a high priority communication to the

control panel. The consumption current increases with this setting.

Note : Applicable subtype setting differs depending on control panels.

Subtype 1 to 10 can be used with the control panel complying with UL864

9th edition.

Subtype 7 to 10 can be used with the control panel complying with UL864

10th edition.

Please contact Nittan customer service for any required details.

Wiring

All wiring must conform to applicable local codes, ordinances, and

regulations.

Install module wiring in accordance with the appropriate wiring diagrams.

Use cable AWG12-22 for wiring. Do not connect different gauge cables

at one terminal in order to prevent loosening. Use a fork terminal for

crimping two cables.

CAUTION

!

Do not connect cables in reverse polarity. Failure to connect the polarity

correctly could result in damage to the module and/or other equipment.

CAUTION

!

Note: All wiring is power-limited and supervised.