DW1401989 Rev.K2

Dec 18, 2019

4

Maintenance

Routine inspection: Ensure the module is secure and undamaged.

Operation Test

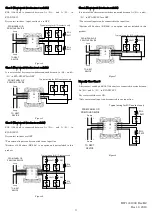

The purpose of the Operational Test is to confirm the product’s correct

operation.

1)

When carrying out site testing of the product, the control panel shall

be set to “one-man-walk test mode” prior to the test.

2)

Take any necessary precautions to limit the sounding of the alarm

sounders/bells and any fire service summoning device.

3)

Turn on the external inputs connected to the module, and confirm

that the module is in active condition and the input LED (red)

illuminates. Confirm that an active signal is transmitted to the

control panel.

Note: If the test cannot be carried out through the external inputs, test the

area between terminal A+ and A-

(

or B+ and B-

)

to check the module. (In

accordance with the subtype setting, set the status either 0

Ω

short (for

subtype 1-4), 2.2k

Ω

short (for subtype 7-9), or open (for subtype 5-6).)

4)

After the external inputs have brought the module into the active

condition, reset the external inputs. Confirm that the module goes

back to the initial status after the external inputs are reset.

5)

If subtype is set as 1-4, or 7-10, open between terminal A+ and A-

(

or

B+ and B-

)

and confirm that the control panel detects the open

circuit. If subtype is set as 5-10, short between terminal A+ and A-

(

or

B+ and B-

)

and confirm that the control panel detects the short

circuit.

6)

Short between terminal Lin+ (Lout+) and Lin- (Lout-), and the SCI

LED (yellow) illuminates. The short circuit isolator isolates the

devices connected after the short-circuited area, which makes these

devices have no response. Upon removal of the short condition, the

area is automatically connected to go back to the normal standby

status, and the SCI LED (yellow) turns off.

FOR WARRANTY SERVICE, RETURN TO:

OVERSEAS BUSINESS DIVISION, NITTAN COMPANY, LIMITED

1-54-5 SASAZUKA, SHIBUYA-KU, TOKYO 151-8535, JAPAN

http://www.nittan.com

Specifications

SLC Applied Voltage

Rated range 20 to 38VDC

SLC Current Consumption

Standby 3.0mA

Activated 16.9mA

(

max

)

SLC Line Impedance

Up to 50 ohms

Number of IDC Circuits

1 x Class A or 2 x Class B

IDC Circuit Rating

15VDC, 2.2k ohms, 6.8mA (max)

IDC Line Impedance

Up to 50 ohms

EOL Device

RE-10k (10k ohms, 1/4W), Class B

only

2.2k ohms EOL required for each dry

contact switch in subtype setting

7,8,9,and 10

SCI on Resistance

0.2 ohms (max)

SCI Fault Detection Threshold

10V (min)

SCI Isolation Current

22mA (max)

Visual Indicator (Status LED)

Polling LED (GREEN)

Input LED (RED)

SCI LED (YELLOW)

Ambient Installation

Temperature

0

℃

to 49

℃(

32°F to 120°F)

Storage Temperature

-20

℃

to 60

℃(

-4°F to 140°F)

Max Relative Humidity

Up to 93

%

RH, non-condensing

Environment

Indoor dry use only

Max. number of units per loop

127 units

Terminal

Screw AWG12 to 22

Address Setting

EVA-AD2 Address Programmer

Dimensions

124mm H x 124mm W x 34.5mm D

(4.882’’ H x 4.882’’ W x 1.358’’ D)

(Mount to a 4’’ square by 2

⅛

’’ deep

box)

Weight

Approximately 153g (5.4oz)

Conformity

UL864