6

・

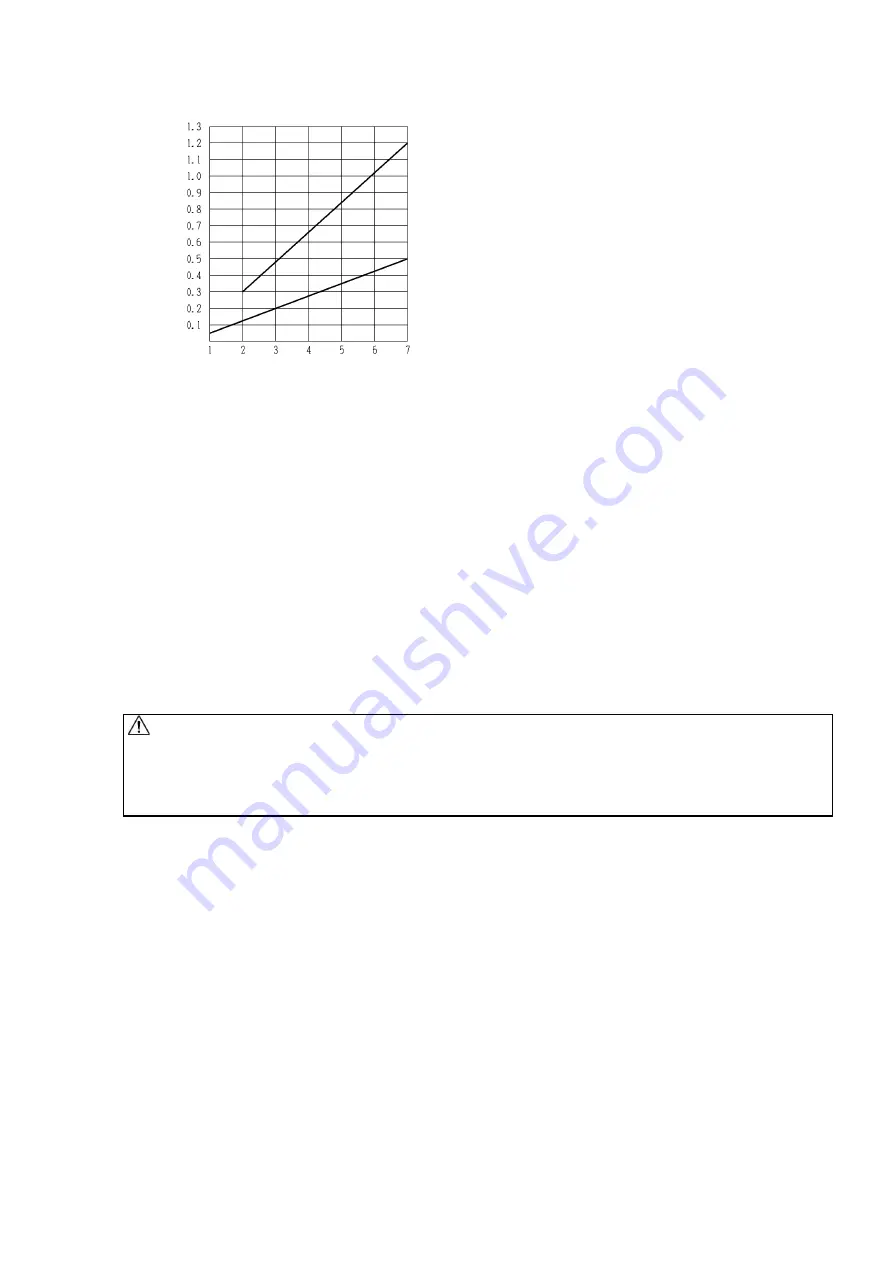

Relationship between Torque and Torque Scale.

*Reference Value

Adjust the bit torque by changing the driving-in length of the torque adjustment ring at the end.

The relationship between torque scale and torque is as shown right, in the torque diagram. The

figures of torque scale do not in dictate bit torque values. However, the clamping torque of screw

itself is different from type, size, material of the screw and the material of its mating part. Use it as

a standard to obtain an appropriate clamping torque.

The [Return torque method] in which once-clamped screw is returned with torque wrench or the

like is available as one of torque control methods. However, note that the measured values by the

return torque method generally appear in 10% - 30% lower than the actually clamping torque.

The torque checker measures the torque of screwdriver. The clamping torque of screw itself is

different from the clamped conditions. Understand the correlation between clamping torque values

and the torque checker values to perform the torque control properly.

CAUTION

Also in reverse rotation, the clutch is turned off in such manner as in normal rotation, stopping

the motor running.

Accordingly, when returning the screw tightened at a large torque, set it to a higher torque scale.

T

or

q

u

e

[N

・

m

]

Torque Scale

DLV7331

DLV7321

Summary of Contents for Delvo DLC1213-LUB

Page 11: ...11 Notes...