3

and may invalidate your warranty.

23. Do not allow the following chemicals to come into

contact with the tool housing, as damage will

result. For example, trichloroethylene acetone,

benzene, thinner, ketone, or other same

chemicals.

2.OPERATION

CAUTIONS

CAUTION

1. Use at the voltage, which is indicated on the rating

plate. If used at a higher voltage than indicated, it

may cause damage and accident.

2. When the tool does not work properly, or you hear

abnormal sounds during usage, switch off

immediately and request the repair work to be done

by an authorized service facility. If you keep on

using the tool, it may cause injury.

3. Install only bits or accessories in accordance with

the operation manual.

4. Grounding is necessary to be assured, especially for

the bit earth type.

5. Whenever setting the torque, switch off the tools

and components.

6. Whenever changing the bit, ensure the changeover

switch is in the "O" (Off) position and the tool is

unplugged.

7. If the rest interval is shorter than three seconds,

the heat of the motor may increase. However, it

differs from the kind of screw or from the fastening

torque.

8. Do not adjust the torque setting higher than the

number of the torque scale mentioned below.

The number on the torque scale does not indicate

the torque value of the screwdriver. The torque

varies according to the type, size, and material of

screws and work. Therefore, use the following

diagram as references to obtain an appropriate

torque.

9. Do not operate the changeover switch when the

motor is running.

10. Do not use this screwdriver for tightening wood

screws.

11. Whenever a tool is not being used, move the

changeover switch to the "O" (Off) position and

unplug the screwdriver.

12. Do not overload to the extent that the motor locks

or the clutch malfunctions. May cause smoke, fire,

failure or injury.

13. If the body is overheating or functioning

abnormally, stop using the driver immediately and

inspect it to see whether any repairs are necessary.

May cause failure or injury.

14. The driver may overheat depending on the type of

screw, type of screw-tightened material, or

frequency of use. To avoid overheating, stop

operating the driver for a time or use several

drivers in alternation.

Overheating may reduce the life of the product or

cause failure, burns, or other injuries.

15. The fastening torque may vary depending on how

the product is operated or held, the type of screw,

and the fastening conditions. Use a torque wrench

or similar tool to check that the fastening torque is

appropriate.

16.

The product’s output torques shown here are the

values obtained with the following measuring

instruments

. This value may differ when measuring

with different equipment.

・

Dedicated device: DLV02/12 series: DLT1173

DLV16 series: DLT1673

3.

S

PECIFICATION

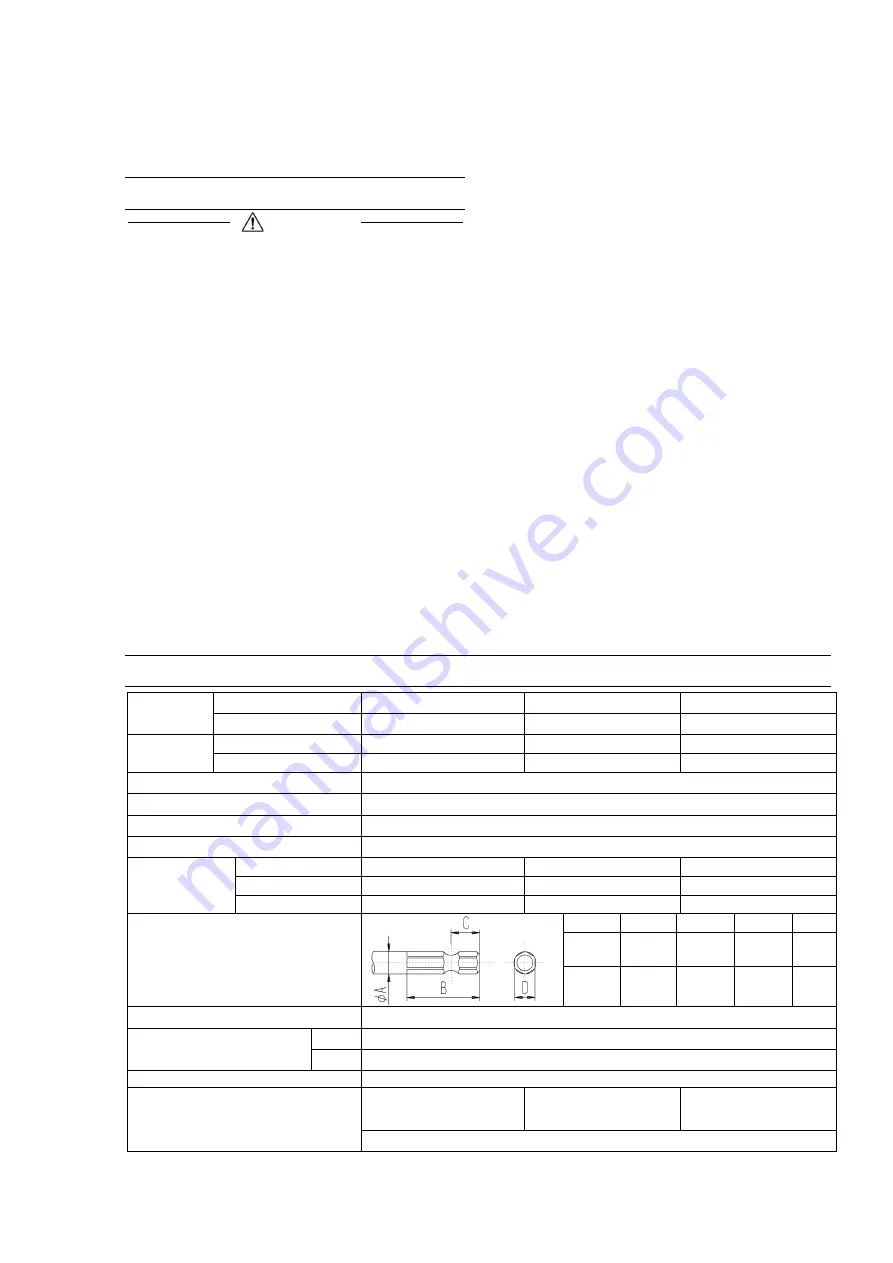

MODEL

Standard

DLV02SL-CKE

DLV12SL-CKE

DLV16SL-CKE

ESD

DLV02SL-BKE

DLV12SL-BKE

DLV16SL-BKE

Torque

[Nm]

0.03

to

0.2

0.15

to

1.2

0.2

to

1.6

[Lb-in]

0.27 to 1.8

1.33 to 10.6

1.8 to 14.2

Free Speed [min

-1

]

700

to

1000

Input Voltage

20 to 30 V DC

Power Consumption [W]

48

Duty Cycle [sec]

0.5 ON / 3.5 OFF

Screw Size

[mm]

Machine Screw

1.0

to

2.2

1.4

to

3.0

2.2

to

4.0

Inch thread

#2 or less

#4 or less

#2 to #8

Tapping Screw

1.0

to

2.0

1.4

to

2.6

2.0

to

3.0

Bit Type

Unit

A

B

C

D

In

0.28

0.91

0.35

1/4

mm

7

23

9

6.35

Mass

0.47 kg / 1.03 lbs

Noise emission

[EN60745-1]

*L

pA

67 dB (uncertainty: K=3dB)

*L

WA

78 dB

Vibration level [EN60745-1]

3.8 m/s

2

Standard Accessories

Bit No.0x3.8x50: 1Pic

Bit No.1x3.8x50: 1Pic

Bit No.1x3.8x50: 1Pic

Bit No.2x4x50: 1Pic

Bit No.1x3.8x50: 1Pic

Bit No.2x4x50: 1Pic

Connection Cable(2.4 m / 7.87 ft): 1Pic