8

5.SERVICE

AND

MAINTENANCE

1.

Have the screwdriver or components repaired by a qualified or trained person only.

2.

For the purpose of making proper use, request the following check and maintenance by an authorized

service facility.

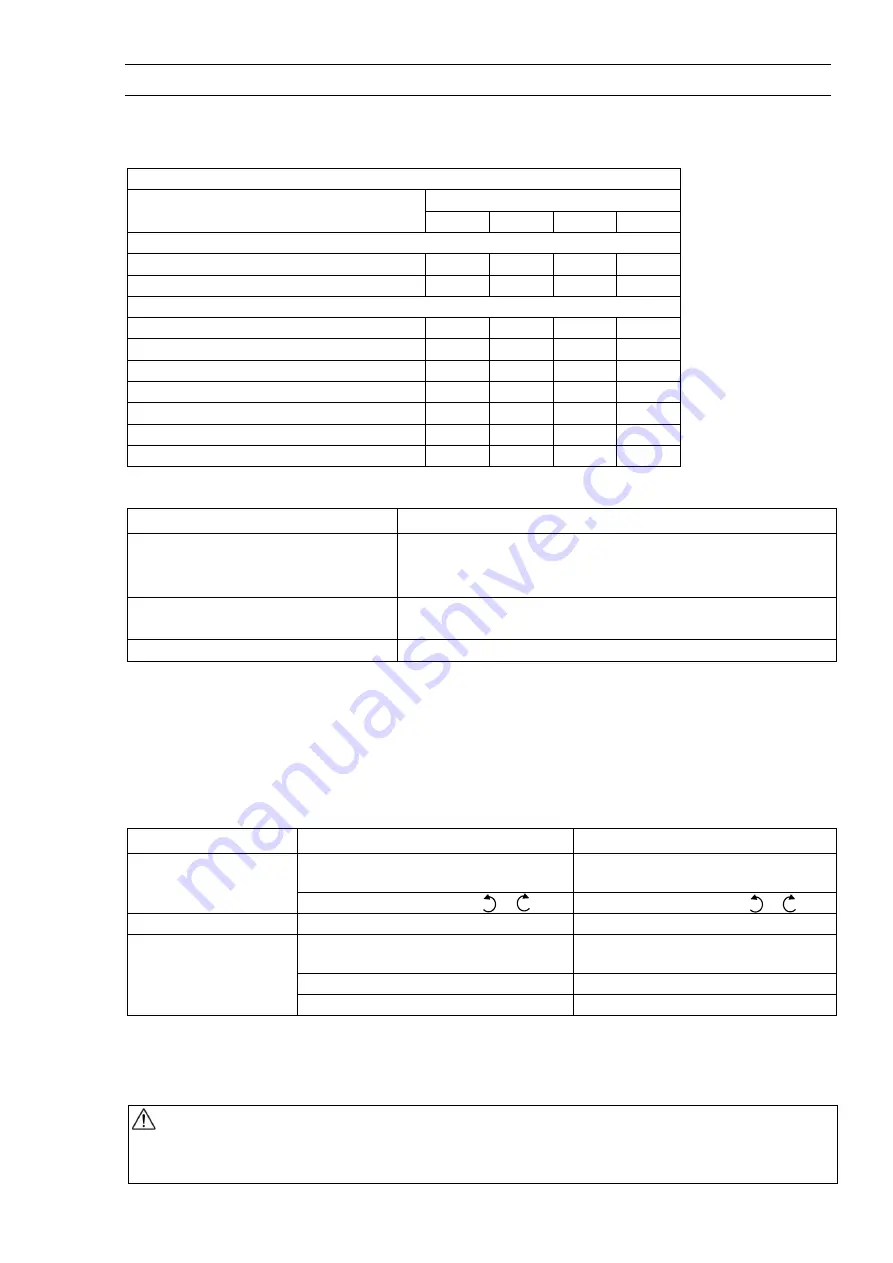

DLV02 / DLV12 / DLV16

Routine inspections and

Parts to be replaced

Number of Tightening (million)

0.5

1.0

1.5

2.0

Routine inspection

(1) Operation check

○

○

○

○

(2) Grease-up

○

Routine inspection and parts to be replaced

(1) Motor assembly

○

(2) Power cord

○

(3) Spindle gear head assembly

○

(4) Gear case assembly

○

(5) Cam rollers and Cam guide balls

○

(6) Cam guide

○

(7) Spindle bearing

○

Contents for operation check

Operation check items

Check procedure

(1) Does screwdriver rotate for both

directions smoothly?

With tool plugged, turn on the reverse switch to forward or reverse

position and turn on the switch.

Then check if the tool rotates smoothly.

(2) Does screwdriver stop at one index of

the clutch?

Check if the motor stops instantly at the moment a screw was

tightened up.

(3) Is the torque decreasing?

Check by torque checker or equivalent.

3.

In case of trouble or repair of this product, contact an authorized service facility

4.

Electric tools, accessories, and packaging should be disposed of for recycling in an environmentally friendly

manner. Do not dispose of electric tools into household waste!

If your tool can no longer be used, deliver it to a sales representative.

Trouble shootings

Problem

Check item

Countermeasures

(1) No Rotation.

Is the power plug of the power cord connected

to the power source outlet?

Connect the power plug of the power cord to

the power source outlet securely.

Is the changeover switch set to " or " ?

Set the changeover switch at " or ".

(2) Output torque is low.

Is the output torque correctly set?

Check it by Torque Checker.

(3) The screwdriver is

overheating abnormally.

How much time is "OFF" time?

Lengthen "OFF" time more than "ON" time.

Check the Rating label of the main body.

Is the input voltage correct?

Check the input voltage.

Is not the maximum scale value exceeded?

Set the torque below the maximum scale.

The Repair Parts List is reference attached sheet.

If the abnormality still does not disappear, contact your sales representative from which you purchased the tools.

WARNING

Please have the product inspected periodically at the store of purchase or a Nitto Kohki-approved service

center. Failure to perform periodic inspections may result in short circuiting.