51

EN

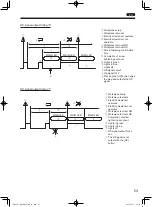

Adjusting the workpiece setup time

You can adjust the time from when workpiece is set (workpiece is detectable) to when the workpiece LED lights.

During this period, you can check whether incorrect workpiece is set. Within the period, moving workpiece does not

cause NG. Also, the electric screwdriver does not operate.

1

Press and hold the [MEMORY] button and [SELECT] button

The mode enters function setting mode.

2

Press the [SELECT] button to select function No. 2

3

Use the [UP] or [DOWN] button to select the workpiece setup time (0.1 - 9.9 sec.)

4

Press and hold the [MEMORY] button to save the setting

Start timing of workpiece setup NG

You can decide at which point workpiece NG starts (NG E7 in case workpiece is removed half way through).

1

Press and hold the [MEMORY] button and [SELECT] button

The mode enters function setting mode.

2

Press the [SELECT] button to select function No. 3

3

Use the [UP] or [DOWN] button to select the workpiece setup NG timing

Setting

Details

0

Upon setting a workpiece

Set workpiece (workpiece LED lights) → Remove workpiece → NG

1

When workpiece is set up

and the screwdriver rotates

Workpiece is set (workpiece LED lights) → Press start switch of electric

screwdriver → Remove workpiece → NG

Set workpiece (workpiece LED lights) → Remove workpiece → NG does not

occur

* This function is useful if workpiece is set but is temporarily removed for such

reasons as position adjustment or setting parts on the workpiece.

4

Press and hold the [MEMORY] button to save the setting

TV07521-1_DLV30S12P-AYK_en.indb 51

2017/02/10 15:56:37