2

EN

1 Application

This is a hand-held electric screwdriver used to tighten screws.

The tool is equipped with an environmentally-friendly brushless motor.

Features differ depending on the model type. For identification of model, see p. 1.

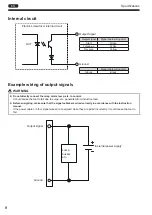

Features of the SP type

This type is a signal output driver with an addition of start signal, torque-up signal, and reverse rotation signal (photo

coupler output) that can be available for security against forgetting to tighten screws.

When the reverse rotation signal is added to the start signal and torque-up signal, this is effective in controlling

the number of screws to be tightened and also can be used to reset the count by using this reverse-rotation signal

when screw tightening has failed and the screw must be loosened by reverse rotation.

Each output signal is a photo coupler output that does not require an external power supply and auxiliary circuit.

Thus, it can be directly connected to the sequencer, etc. and facilitates signal processing.

The driver power supply is insulated from the output signals by a photo coupler, ensuring safety.

Features of the SPC type

This tool is only for screw fastening counter DLR5040A-WE and DLR5340-WE. Use it in combination with the screw

fastening counter.

For how to use the screw fastening counter, refer to the instruction manual of the screw fastening counter.

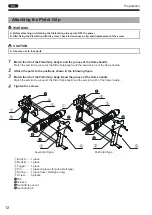

2 Checking Inside the Package

When you open the package box, check the content of the package and also check for any damage caused by

incidents during transportation.

If a problem is found, consult with the store where you purchased the product.

Package content and list of accessories

DLV30A series

DLV45A series / DLV70A series

Package content and accessories

Quantity

Package content and accessories

Quantity

Electric screwdriver (main unit)

1

Electric screwdriver (main unit)

1

Bit NK35 (No.2×7×75) (HEX 5 mm) *

1

Bit NK31 (No.2×6×70) (HEX 6.35 mm) *

1

1

Bit NK35 (No.2×7×75) (HEX 6.35 mm)

1

Suspension Bail

1

Low Torque Spring

1

Pistol Grip DLW2300

1

High Torque Spring *

2

1

Instruction Manual

4

Suspension Bail

1

Instruction Manual

4

*1 Bits differ depending on the model. Please refer to p. 3.

*2 The high torque spring is built inside the main unit at the factory default.

White paint

Low Torque Spring

6.35

75

Ø

7

9

hexagon width across flats

Phillips No.2

Bit NK35 (No.2×7×75)

High Torque Spring*

5

70

Ø

6

14

hexagon width across flats

Phillips No.2

Bit NK31 (No.2×6×70)