8

Remember that chamfering level changes depending

on the radii in this case.

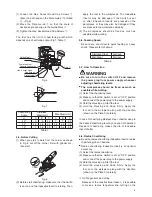

Fig.13

Plate D

Min.12

Fig.14

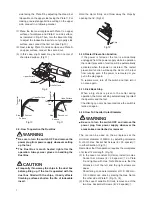

6. HOW TO REPLACE INDEXABLE INSERT

WARNING

●

Be sure to turn the switch OFF and remove

the power plug from power supply whenever

replacing Indexable Insert.

●

The Indexable Insert and the Holder are much

heated right after the operation. Always wear

gloves in handling the Indexable Insert and the

Holder.

(1) Lay down the Knob with it pulled up. (Fig.15, 16)

(2) Open the Lock Plate with the Knob laid down.

(Fig.17)

(3) Remove the Indexable Insert Set Screw using the

Spanner T-15D attached to take off the Indexable

Insert. (Fig.17)

(4) Mount a new Indexable Insert (including use of

reverse surface) paying attention to the direction of

the IndeXable Insert. (Fig.17)

(5) Close the Lock Plate with the Knob laid down and

lay the Knob aside to lock it. (Fig.18)

PULL

UP

Knob

Fig.15

LAY

DOWN

Fig.16

OPEN

Lock Plate

Indexable Insert

Indexable Insert

Set Screw

Fig.17

CLOSE

①

PUSH

②

Fig.18

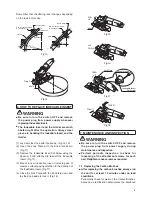

7. MAINTENANCE AND INSPECTION

WARNING

●

Be sure to turn the switch OFF and remove

the power plug from power supply during

maintenance and inspection.

●

Perform periodic inspection to check for

loosening of the attachment screws for each

part. Retighten loose screws as required.

7-1. Replacing the Carbon Brushes

●

After replacing the carbon brushes, always run

the unit for at least 10 minutes under no load

conditions.

Periodically check for wear on the Carbon Brushes,

because as rectification deteriorates the likelihood

Plate D

A

φ

200

〜φ

300

Hex. Nut M8

①

Hex. Socket Set Screw

8

×

25 special

①

A

Hex. Socket Set Screw

8

×

25 special

①

Hex. Nut M8

①

Dimension

Ball Shape

Min.

φ

300

A

A

Plate D

Summary of Contents for EMB-0307B

Page 13: ......