BOLTWORK REQUIREMENTS and MOUNTING SPECIFICATIONS

If the Duet Rotobolt lock is used in conjunction with another lock, the boltwork must be constructed in a

way that the Universal secures first.

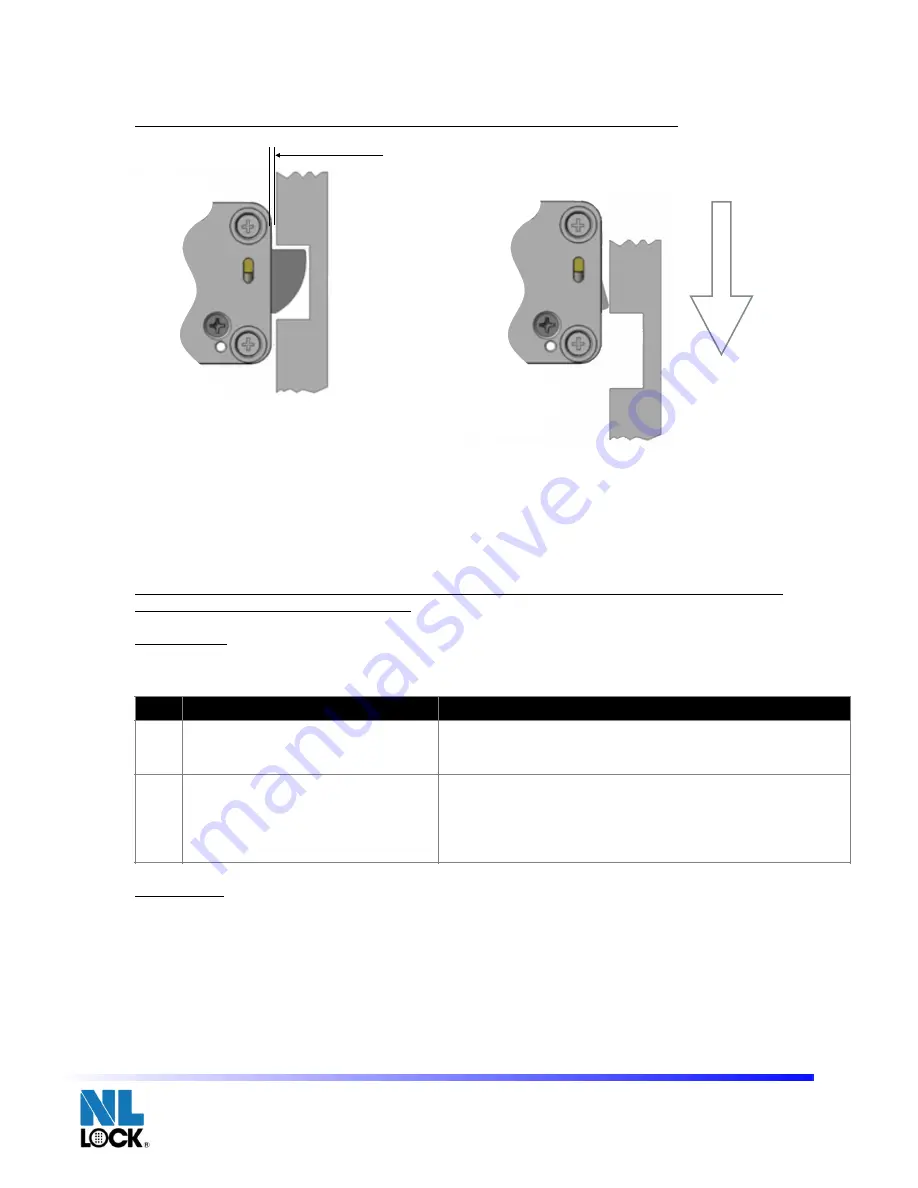

In the LOCKED position the distance between the Universal bolt and the boltwork part that is moving the

lock bolt should be approximately 1 mm.

Only use NL LOCK supplied screws (M6) to mount the lock. Lock has to be mounted on secure storage metal

(preferred steel) units only. Tighten the screws securely so the lock body is attached firmly to the mounting

surface. Use of screw locking glue (i.e. Loctite) is recommended.

Security relevant parts of a HSL should not be accessible to unauthorized persons when the door of the

secure storage unit to which it is fitted is open

Test Electronics

Like all locks from NL LOCK this unit includes a unique feature to functionally test the electronics:

Function #5

Functional Test

•

Enter code (i.e. 1-2-3-4-5-6). The lock emits a double signal for the correct code.

•

Turn boltwork handle towards OPEN position.

The bolt rotates into the housing. Bolt must move freely.

•

Turn handle towards Locked position.

The lock bolt must fully extend and secure.

•

Make sure there is an air space on all sides of the lock bolt when the safe’s boltwork is fully thrown

into locked position.

IMPORTANT: Perform the functional test several times before locking the safe door.

RR40•20 Technical Manual rev. 170528

© 2017 Lock Technology Page

!

of

!

2

4

STEP

TASK

REMARK

1

Press and hold [5] until a double

signal sounds and the light stays ON.

2

Enter the all keys in exactly this

sequence:

[1]-[2]-[3]-[4]-[5]-[6]-[7]-[8]-[9]-[0]

Push buttons slowly so you recognize the signaling of the

lock. A double signal indicates that the keypad and the lock

communicate and perform properly.

A long signal indicates that the electronics may be damaged.

Lock bolt operations only allowed as described

into the drawing and max load should not

exceed 1KN.

min 1.5 mm.