11

10

Contact electromagnetic

field distribution

Magnetic quenching principle

Moving

contact

Fixed

contact

Arc is pushed into

arc extinguish

chamber by

magneto-mechanical

effect

Current limit type

Current limiting means to keep the short circuit current in the circuit being protected lower than

expected value. With the protection of current limit type Ex9M circuit breaker, the peak short

circuit current value and I

2

t energy will be significantly lowered in case of short circuit.

Current limiting can reduce the heat effect, electrodynamic effect and electromagnetic effect

of short circuit current. It can also reduce the damage caused by short circuit current to lines,

equipment and circuit breaker.

If the upstream circuit breaker is equipped with current limiting capability, which can lower the

requirements for the breaking capacity of downstream circuit breaker and achieving cascade

(backup) protection

If both the upstream and downstream circuit breakers are equipped with current limiting

capability, the system can provide selective protection, in which case only the closest circuit

breaker will be disconnected if fault occurs.

U type fixed contact design

The unique U type contact enables pre-breaking technology:

The pre-breaking technology means when the short circuit current goes through the contact

system, the electric force generated on the U type fixed contact and the moving contact are

repulsive; the bigger the current, the bigger the force, and the force is generated at the same

time as the short circuit current; before release, the electric repulsion force can break the fixed

and the moving contacts, increasing the equivalent resistance between them by extending the

arc, so that the increase of short circuit current is suppressed.

Double breaking point design

The unique double breaking point design can increase instantaneous arc resistance and arc

voltage, and significant lower current increase rate, which enhances the current limiting effect

of the pre-breaking technology; it can improve safety by lowering the harm and damage caused

by short circuit current to equipment and circuit; it also enables cascade which can reduce the

cost for downstream protection equipment.

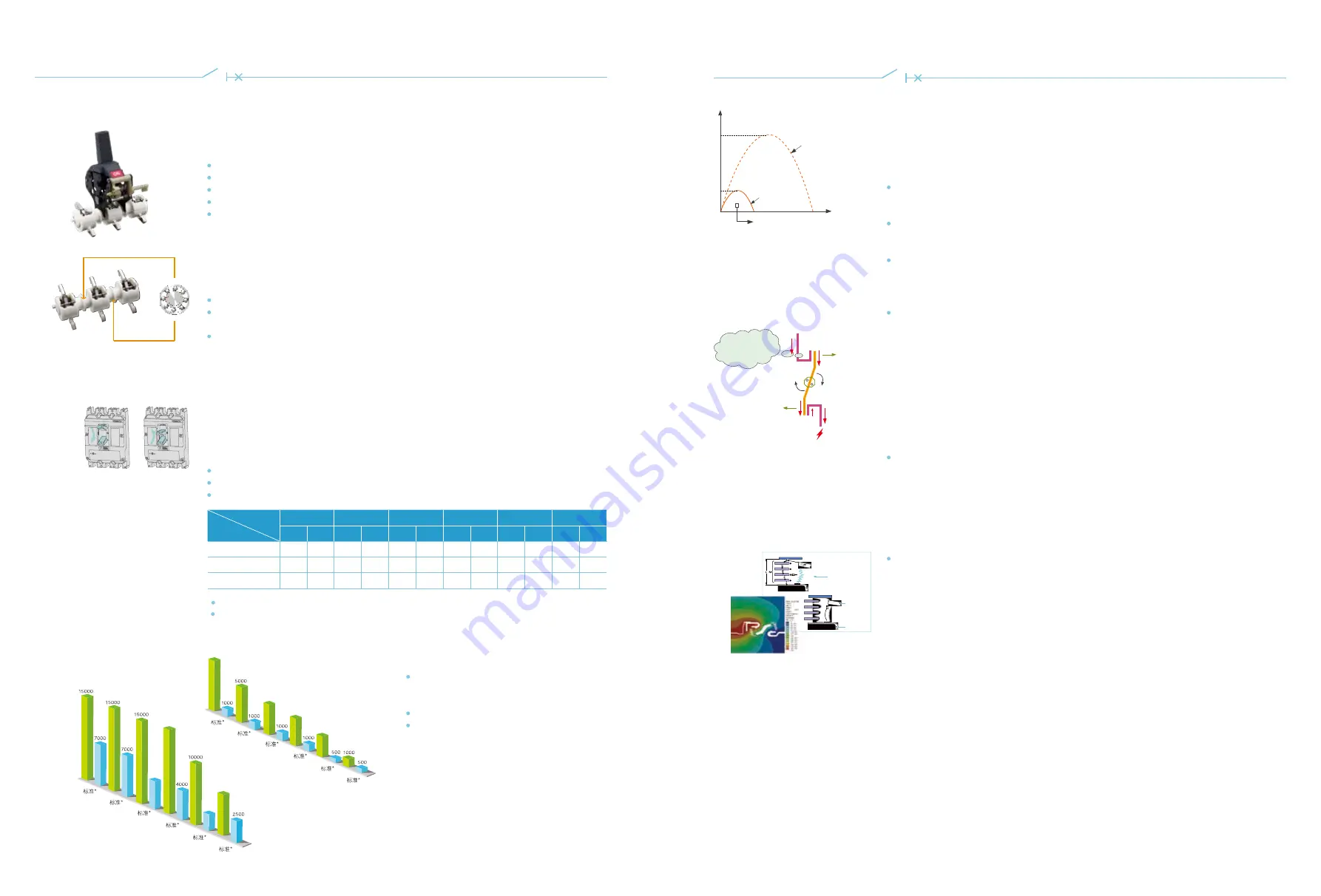

Zero flashover

Electromagnetic field simulation analysis ensures the arc extinguishing capability of the circuit

breaker so as to achieve zero flashover.

We use comprehensive and advanced electromagnetic field software simulation technology

for the design of arc extinguish chamber and the fixed and moving contacts of the circuit

breaker, to make sure the generated arc is blown into the arc extinguish chamber instantly. By

using magnetic quenching method, we significantly improved the arc extinguishing capability

of the circuit breaker and further enhanced it’s current limiting capability.

I

T

Expected peak

Expected short

circuit current

Actual peak

Actual short circuit current

after current limiting

Energy after current

limiting

I

I

U type rejection circuit,

enhanced repulsion

force for fast breaking

of contact

Upper fixed contact

Force F1

Moving

contact

Lower fixed

contact

Force F2

Bearing type

The operating mechanism is a key component of the circuit breaker, the key technical parameters

and performance of the circuit breaker is closely related to the operating mechanism:

Rotary shaft is a key component of the circuit breaker:

Mechanical life (times)

Ex9M – a durable high-performance circuit breaker:

Service life of the circuit breaker

Breaking capacity of the circuit breaker

Breaking speed of the circuit breaker

Operating force of the circuit breaker

Operation reliability of the circuit breaker

It is a rotary part inside the circuit breaker, which will operate tens of thousands of times

It guarantees the synchronized disconnecting and connecting of the three phases (or four phases)

of the circuit breaker

The wear of the rotary shaft will affect the performance of other parts which can increase risks

Extend the service life of circuit breaker by times

2 times of standard, decrease the frequency for

replacement and cost for maintenance

Significantly improve the reliability of the product

The use of accessories is not affected by

operation times

Reliably improved breaking capacity: ensure

I

cs

=I

cu

, without derating in reverse wire entering application.

Increase breaking speed by times: breaking time < 2ms

Significantly decrease operating force: less than 3/5 of similar products

The friction between the rotary shaft of a traditional circuit breaker and its adjacent parts is

sliding friction, which can generate high frictional resistance and therefore cause larger wear to

the rotary shaft. This can be the biggest issue that limits the breaking speed and the service life

of the circuit breaker.

Noark developed a new type of rotary shaft that generate rolling friction which eliminated all

the issues that created by sliding friction and thus significantly improved the performance of the

circuit breaker.

Manual operation of Ex9M: easy and flexible

Electric operation of Ex9M: lower power consumption of motor

Model

Operating force

Ex9M1

Ex9M2

Ex9M3

Ex9M4

Ex9M5

Ex9M6

3p

4p

3p

4p

3p

4p

3p

4p

3p

4p

3p

4p

Making force (N)

44

46

55

82

120

160

160

200

160

200

250

255

Breaking force (N)

24

24

39

55

110

150

150

195

150

195

170

175

Re-trip force (N)

36

38

36

54

150

220

165

215

165

215

260

265

Electrical life (times)

Features

Features

8000

4000

4000

15000

2500

6000

3000

2000

Ex9M6

Ex9M5

Ex9M4

Ex9M3

Ex9M2

Ex9M1

Ex9M6

Ex9M5

Ex9M4

Ex9M3

Ex9M2

Ex9M1