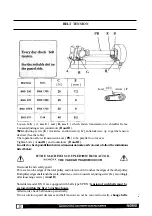

BELT TENSION

A

B'

I

Load

Arrow

( F

Loosen bolts

(

A,

no.

4

)

and

(

B,

no.

1

)

which fasten transmission to shredder frame.

Loosen adjusting screw counternuts

(

H

and

D

).

Turn

adjusting screw

(

E

)

clockwise, and turn screw

(

G

),

anticlockwise, up to get the tension

desired (See the table).

That operation allows transmission axis

(

PR

)

to be parallel to rotor axis.

Tighten bolts

(

A

and

B

)

and counternuts

(

D

and

H

).

In

order to check parallelism between transmission

axis

and rotor

axis,

follow the indications

listed below:

IF THE MACHINE

IS COUPLED

TO

THE TRACTOR,

THE

CARDAN TRANSMISSION

Dismount the belt safety guard.

Put a scale on the edges of the rotor pulley and rotate it until it touches

the

edges of the other pulley.

Both pulley edges shall touch the scale;otherwise, screw or unscrew adjustingscrew

(G

)

accordingly,

after loosening screws

(

A

and

B

).

Shredders model

BNG are equipped with belts type SPBX

:

tension

of

such belts must be

restored within the first

3

working hours.

Afterwards, check belt tension periodically.

If rotor rotation speed decreases and belt tension can not

be

restored correctly,

change belts.

I

C

E