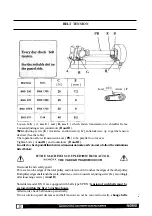

TROUBLESHOOTING

Problem

Excessive vibrations

Poor cutting due to rotor

low speed.

Belt"overheating

Bevel gear pair

overheated.

Quick wear of blades or

rams.

Oil

leaking from

transmission

unit,

belt

side.

Roller or wheel supports

warped.

Safety vanes are warped.

Cause

Remedy

A)

Blades or rams worn or

B) Blades or rams locked by

C)

Rotor balancing not correct.

D) Rotor bearings worn.

Replace worn-out or broken

Clean and grease pins.

Check the weight of blade or

Dismount and replace bearings

broken.

parts.

pins.

ram units.

and seals.

(

A) Belt tension really poor.

Adjust belt tension.

B) Worn-out belts. Replace

belts.

A) Belt tension not correct.

Check tension.

B)

Transmission axis and rotor

Check alignment.

axis not aligned.

A) Lack of oil

B) Oil spent.

Top

up

oil.

Replace.

A) Working position too low,

Adjust the height of rotor with

respect to the ground.

blades or rams

are

touching

the

ground.

A) Oil retainer broken or

worn.

Replace oil retainer.

A) Roller or wheel supports

Raise

up

the machine from the

suffered from lateral strain.

ground when you change

gear.

A)

In order to reach the working

Make the machine get to its

working position

before

position, the raised machine

(trasport position), was

shredding.

lowered

onto

the material to

shred.