Shredders

40

6. - Putting into service

TBE GBseries 102

JN070AGB B

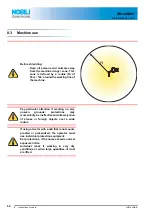

6.1.6 Antishock unit

The safety breakback is made up of 2 traction

springs and a tension adjustment system.

The safety breakback allows the shredding unit to

pivot rearwards and to regain automatically its initial

position after having cleared the obstacle.

The safety breakback is adjusted by means of nuts

(1). The measure (X) is factory set at

80 mm (3’3’’): This adjustment suits most conditions

of use.

1

1

X

X

1

1

X

X

By increasing length (X), the safety breakback

force is reduced.

By reducing length (X), the safety breakback

force is increased.

The 2 springs must adjusted to the same

measure.