Use and Maintenance Manual model “A13V - C ZENITH & A13 V PLUS ZENITH”

22

ENGLISH

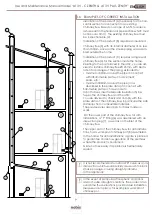

11.3 EXTRACTION/PELLET MIX

The PELLET-EXTRACTION mix setting

allows you to change, with immediate effect, the

quantity of pellets loaded in the brazier and the

quantity of air inbound of the product, tested and

inspected with DIN PLUS certified pellets. If you use

other pellets or uncertified pellets, combustion

may need to be adjusted. Normally,

the change is executed on the EXTRACTION percent-

age to improve combustion; if oxygen adjustment is

not

efficient, you may need to also change the

percentage of PELLETS falling.

OPERATING PROCEDURE:

MENU >> SET USER >> P/E MIX

Access the menu by pressing key

Scroll the items to SET USER, key

Access the menu by pressing key

Scroll the items to P/E MIX with the key

Access the function by pressing key

OK

OK

OK

OK

Edit the pellet setting with the keys

The values vary from -5: reduction in pellet load in %

to +5: increase in pellet load in %

Confirm by pressing the key and pass

to edit extraction.

OK

Edit the extraction setting, keys

The values vary from -5: reduction in extraction in %

to +5: increase in extraction in %

Confirm by pressing the key and exit

adjustment

to return to the SET USER screen.

As for example outlined above, a percentage of -2

PELLET and +3 EXTRACTION was set;

this kind of setting results from the fact combustion is

lacking oxygen and the

pellets are small in size compared to the average

2cm.

OK

Select the type of screen you want to

display, with the keys

Access the relevant screen with the key

During editing, remember that:

• to return to the previous data, without saving

the last data changed, press the key

•

if you intend changing a single datum, having ter

minated the change, press the key multiple times

until you exit the function described in the

paragraph.

To return to the STAND-BY screen, use the

key , repeating the operation multiple times.

OK

The number indicated, for setting change, refers to

a percentage change which

acts on the default parameters set on the

electronic board, this only affects the work phase.

These values should be changed in the event of

poor combustion, due in many cases to use of pel-

lets different from those used for testing the appli-

ance.

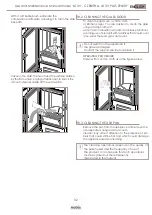

11.4 STOVE STATUS

This function allows you to check the most important

parameters are working properly on the

appliance. Two screens are outlined below

which show the list of real data of the product, useful

for the support service during the control phases.

OPERATING PROCEDURE:

MENU >> SET USER >> STOVE STATUS

Access the menu by pressing key

Scroll the items to SET USER with the key

Access the menu by pressing key

Scroll the items to STOVE STATUS with the key

Access the function by pressing key

OK

OK

OK

OK

OK