Use and Maintenance Manual model “A13V - C ZENITH & A13 V PLUS ZENITH”

9

ENGLISH

ENGLISH

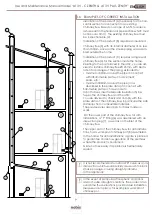

3.6 EXAMPLES OF CORRECT INSTALLATION

installation of the product (A) necessary for the hori-

zontal section for connection to an existing

chimney flue. Based on a slope of 3-5%, to reduce

ash deposit in the horizontal pipe section which must

not be over 3m (1). The existing chimney flue must

be inspectionable (2).

Installation of the product (B) requires an insulated

chimney flue

(3) with an internal diameter of no less

than 100mm, since all the smoke piping was assem-

bled outside the home.

Installation of the product (C) requires a single wall

chimney flue

(4) for the section inside the home.

Relating to the part placed in the attic, you are ad-

vised to install a chimney flue Ø120mm, with perfo

-

ration for passage of the piping, extended to:

•

minimum 100mm around the pipe if in contact

with inflammable parts such as cement,

bricks, etc.;

•

minimum 300mm around the pipe (or as

described in the plate data) if in contact with

flammable parts such as wood etc.

In both cases, insert adequate insulation (5) be-

tween the chimney flue and the attic.

You are advised to check and comply with the

plate data of the chimney flue, in particular the safe

distances from combustible materials.

The previous rules also apply for holes made on

walls.

On the lower part of the chimney flue, for all

3

installations, a “T” fitting (6) was assembled with an

inspection plug (7), as well as on the inlet of the

chimney flue.

The upper part of the chimney flue, for all

3 installa-

tions, has a wind-proof chimney pot (8) assembled.

In the home, for all 3 installations, a grate is planned

to guarantee correct oxygenation of the premises

where the product is positioned.

Grate not necessary if appliance is hermetically

sealed.

It is not recommended to install a 90° curve as an in-

itial section which would quickly cause ash to block

smoke passage, causing draught problems

in the appliance.

9

6

7

7

A

1

2

3

3

4

5

8

8

8

6

9

9

6

7

In the event of particular atmospheric conditions

and/or hostile draught conditions, the product can

overcome these situations provided due installation

measures are in place, for example a wind-proof

chimney pot.

B

C

6