Use and Maintenance Manual model “H14 V SHAPE”

7

ENGLISH

ENGLISH

3

INSTALLATION

The assembly position must be chosen based

on the environment, the discharge and the chim-

ney flue. Check, with your local authority, if there are

more restrictive provisions regarding the oxidising air

intake, the smoke discharge system including the

chimney flue and chimney pot.

The manufacturer cannot be held in any way liable

in the event of installation non-compliant with legisla-

tion in force,

of incorrect premises air exchange or electrical con-

nection non-conforming with standards and/or inap-

propriate use of the appliance.

Installation must be carried out by a qualified techni

-

cian, who will issue the purchaser with a Declaration

of Conformity for the system and will assume com-

plete responsibility for final installation and resulting

good operation of the product.

In particular, he should ascertain:

• there is an adequate oxidising air intake and good

smoke discharge compliant with the type of prod-

uct installed;

• other stoves or devices installed do not cause

negative pressure in the room where the product is

installed (only for hermetic appliances, a maximum

of 15 Pa depression in the surroundings is permitted);

• when the product is on, there is no smoke back

draught in the surroundings;

• smoke evacuation is implement in total

safety (dimensioning, smoke seal, distances from

flammable materials..).

Once the position is decided where to install

the product, you need to pay attention:

• if the floor is made of combustible material,

you should use protection in suitable material (steel,

glass...) which also protects the front part from any

falling burning fuel during

cleaning operations:

• that the floor guarantees adequate

load capacity.

if the existing building does not meet this

requirement, you should take appropriate measures

(for example a load distribution plate).

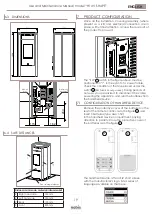

3.1 AIR INTAKE

The installation premises of non-hermetic appliances

must be sufficiently ventilated with specific openings,

with particular attention on the

position (they must NEVER be blocked), which consent

air reintegration in the environment.

The air must be taken directly from outside (not from

other rooms, garage, etc.) and must have a net useful

section equal or higher than 80

cm

2

pellet burning stoves and thermostoves (EN 14785)

and 100 cm

2

for boilers (EN 303-5).

The air intake is not necessary for

installation of the hermetic appliances that take air

directly from outside. Check and

comply with the ventilation requirements for simul-

taneous operations with other combustion devices

and in the presence of forced ventilation systems or

hoods (refer to section 6.4 of UNI 10683).

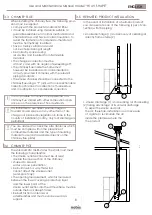

3.2 SMOKE CHANNEL AND FITTINGS

The term smoke channel indicates the piping con-

necting the appliance to combustion with the

chimney flue.

For heat generating appliances with an electric fan

to expel the smoke, the following installation instruc-

tions must be followed, provided by the manufactur-

er concerning the maximum length and number of

curves the smoke channels can have.

If no indications are given for maximum values or

deriving from preliminary calculations according

to UNI EN 13384-1, the following provisions must be

applied:

• comply with the product standard EN1856-2;

• the horizontal sections must have a minimum slope

of 3% upwards;

• the length of the horizontal section must be

minimal and its projection on plan must not ex-

ceed 4 metres;

•

the number of changes of direction including

introduction in the chimney flue and excluding

that by effect of using a “T” element

in the appliances with rear smoke output, must

not exceed 3;

•

the changes of direction must not have an angle

over 90°(45° curve recommended);

•

the section must have a constant diameter

equal to the output of the fireplace up to the

fitting in the chimney flue;

• it is forbidden to use flexible metal and fibre ce

-

ment piping, furthermore the piping must guarantee

pressurised sealing;

•

the smoke channels must not cross premises

in which installation is forbidden of combustion

appliances;

•

Use watertight piping with silicone gaskets.

In any case, the smoke channels must be

sealed by combustion and condensate

products, as well as insulated if passing

inside the installation premises.

Assembly is not permitted of draught manual adjust-

ment devices on forced draught appliances.

You need to install a first vertical smoke channel sec

-

tion of at least 1 metre to guarantee correct smoke

ejection.

All local and national legislation and European

standards must be met when installing and using the

the product.