11

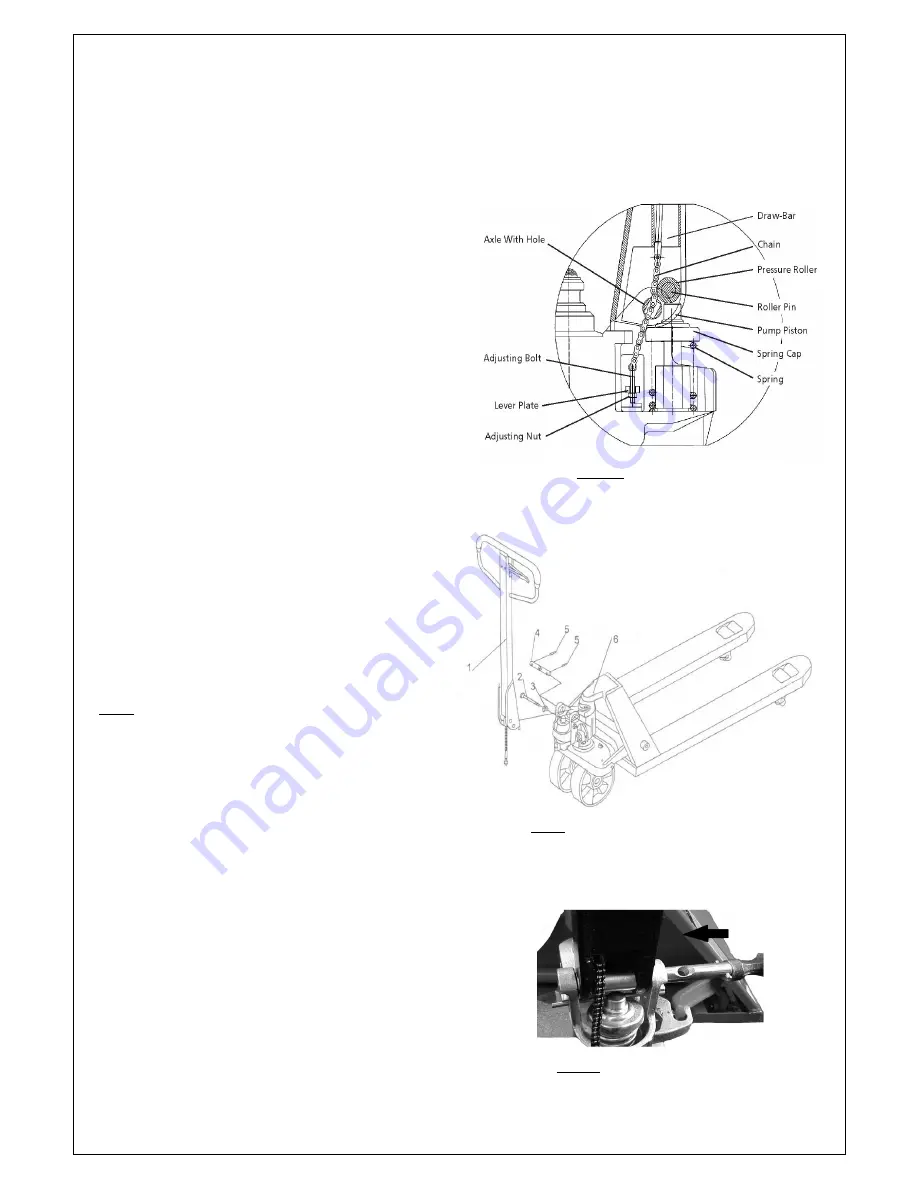

Fig. 6:

Axle assembling

Practice maintenance work according to regular Inspection. This truck is not designed to be water resistant,

therefore use it in dry atmospheres.

4. COMMISSIONING, TRANSPORTING, STORAGE/

REASSEMBLING

a.

Commissioning – Tiller assembling

After receiving our new scissor lift pallet truck you may

have to do following before firstly operating the truck:

•

Check if are all parts included and not damaged

•

Do the work according to the daily inspections as well

as functional checks.

•

Eventually assemble the truck according to following

instructions.

The commissioning weight is approximately 10kg / four-

pack

higher than the product weight.

Before assembling, please make sure, that the following supplied parts are included and not damaged:

•

1 pc axle with hole (4)

•

2 pc dowel pin (5) [one is already assembled with

the axle]

•

1 pc pre- assembled tiller arm (1)

•

1 pc pre- assembled chassis with pump unit (6)

•

Connect the plug(optional for electric model)

(

Fig.

1, pos. 10

)

Note: The marked number on the tiller arm

package and the chassis should be the same.

When attaching the handle, you had better squat

just in front of the pallet truck.

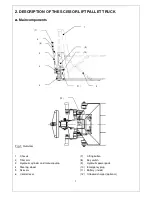

a) Insert the tiller arm(1) into the pump piston

,

then

use a hammer to insert the axle with hole into the

hydraulic pump and tiller arm from the right to the left

(Fig. 6 ).

b) Set the control lever of the handle to the

‘LOWER’ position, then pass the adjusting nut, adjusting bolt

through the hole of the axle with your hand

(Fig. 7).

c) Press the tiller arm down; take away the pin

(2, Fig. 5).

d) Set the control lever of the handle to ‘QUICK LIFT’ (LIFT)

position, then raise the lever plate with the pin (2, Fig. 5) and

insert the adjusting bolt into the front slot of lever plate. Note:

Keep the adjusting nut under the lever plate.

Fig.5

Tiller assembling

(

symbolic

)

(1 Tiller arm / 2 Pin / 3 Nut / 4 Axle with hole /

5 Dowel pin / 6 Chassis with pump unit)

Fig. 7: Side view

(

symbolic

)