13

c.

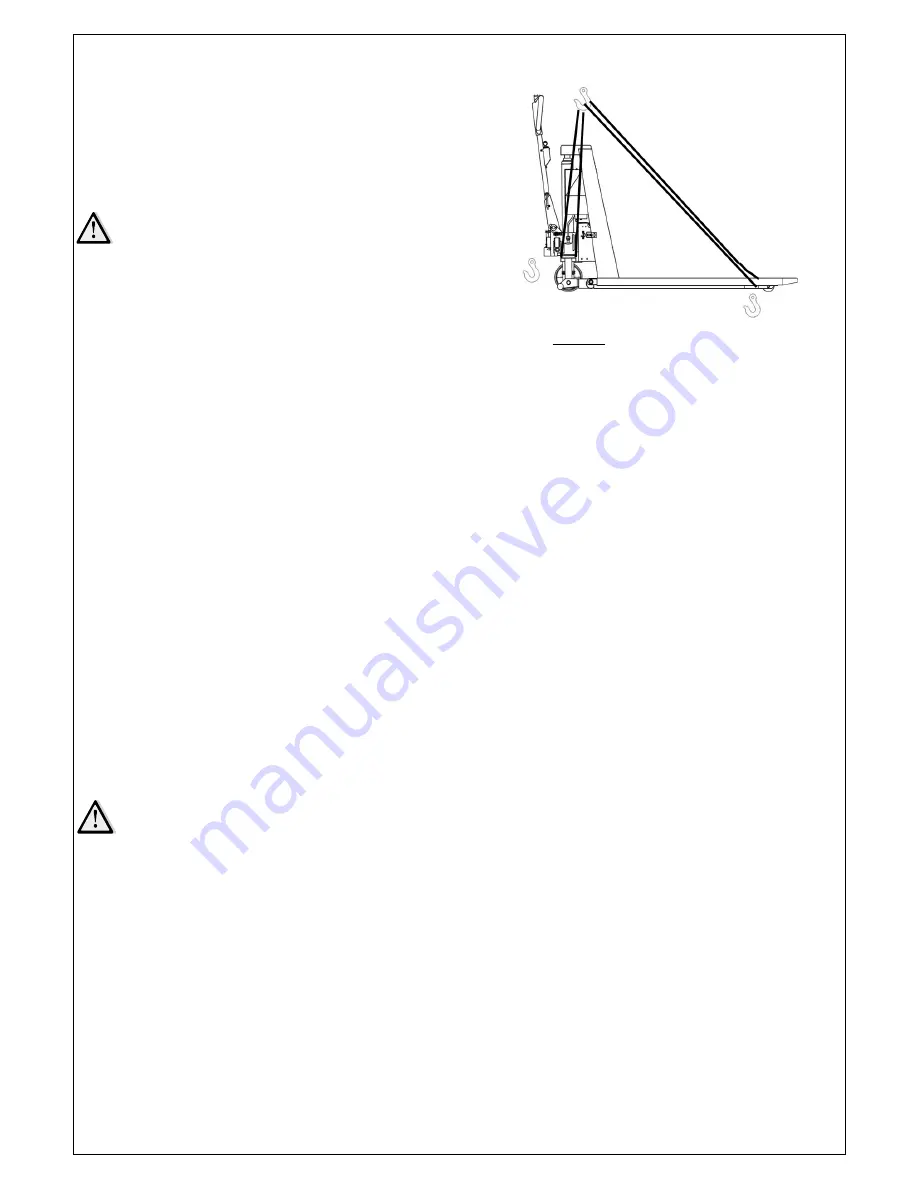

Lifting/ Transporting

Lifting

USE

DEDICATED

CRANE

AND

LIFTING

EQUIPMENT

DO NOT STAND UNDER THE SWAYING LOAD

DO NOT WALK INTO THE HAZARDOUS AREA

DURING LIFTING

Park the truck securely and lash the truck according to the

points identified in fig. 10. Lift the truck to its destination and

place the truck securely before removing the lifting gear. The lashing points are according to the fig. 10

Transportation

For transportation, remove the load, lower the truck to the lowest position and lash it safe with dedicated

lashing straps.

d.

Storage/ Reassembling

For storage, remove the load, lower the truck to the lowest position, grease all in this handbook mentioned

greasing points (regularly inspection) and eventually protect the truck against corrosion and dust. Jack the

truck safety, so that there will be no flattening after storage. Reassemble the tiller in the opposite direction

of the assembling.

5. DAILY INSPECTION

This chapter describes pre-shift checks before putting the truck into operation.

Daily inspection is effective to find the malfunction or fault on the truck and can maximize the lifetime.

Check the truck on the following points before operation.

Remove load from truck and lower the forks to the lowest position.

DO NOT USE THE TRUCK IF ANY MALFUNCTION OR FAULT IS FOUND.

•

Visually check for structural deformation or cracks of arms, forks, or any other component;

and unusual noise or binding of the lifting mechanism.

•

Check if there is any oil leakage.

•

Check the vertical creep of the lifting mechanism.

•

Check the smooth movement of the wheels.

•

Check if there are any particles or damages on the wheels.

•

Check if all the bolts and nuts are tightened firmly.

•

If equipped, check the brake.

•

Verify that all labels are in place.

Fig. 10: Lifting with a crane