49

4.1 OPERATION OF PUMP STATION

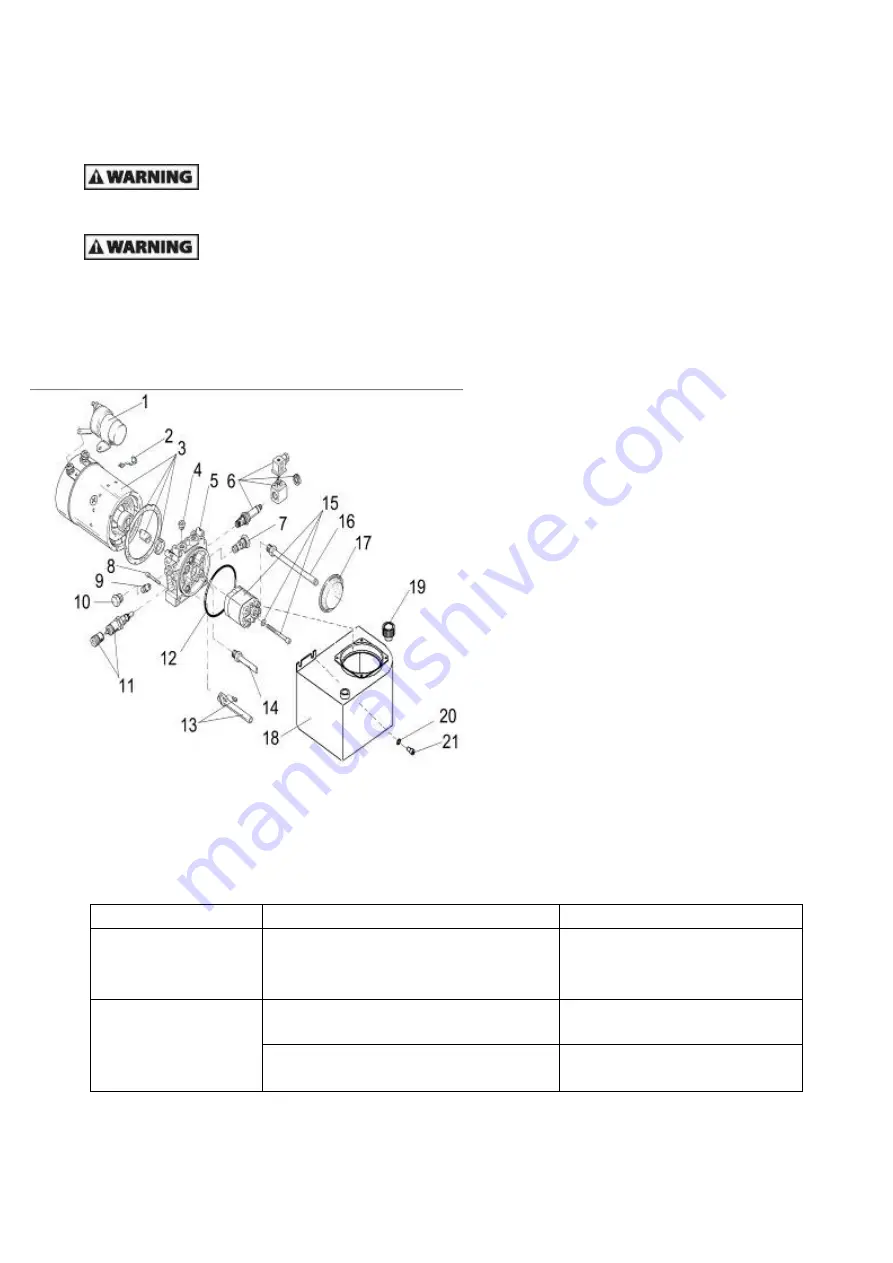

REPLACE THE PUMP STATION

Put the fork of the ground and drain out the hydraulic oil.

CLEANING OIL TANK AND FILTER

Put the fork of the ground and drain out the hydraulic oil.

Remove out the pump station

Take away two screws (No.21)

Remove the suction filter (No. 16 & 17).

Clearning of oil tank and filter.

Clean the Fix plate for valve (No.5), etc.

Clean up with compressed air and

inspect if the filter is stopped or damaged.

If the filter is stopped or damaged,

replace it.

Remove dust or foreign material from the

tank.

Then assemble them.

TROUBLE DIAGNOSTICS

Symptom

Abnormality and cause

Countermeasure

Bubble in hydraulic oil Mixed with air

Check if there is any place

where air can be enteted.

Tighten the loosened part again.

Discoloration

Mixed with air and water

Replace the oil.

Became inferior in quality by oxidizing or

mixed with other particles.

Replace the oil.

Summary of Contents for CG1646

Page 16: ...18 3 ELECTRIC SYSTEM 3 1 ELECTRIC DIAGRAM WIRING DIAGRAM ...

Page 19: ...21 CG1646 Universal Electric Parts List ...

Page 31: ...33 3 7 CURTIS CONTROLLER ...

Page 50: ...52 5 DRIVE WHEEL 5 1 THE DRIVE WHEEL Driving Wheel MR250FR ...

Page 64: ...66 9 2 TROUBLE SHOOT ...

Page 65: ...67 ...