65

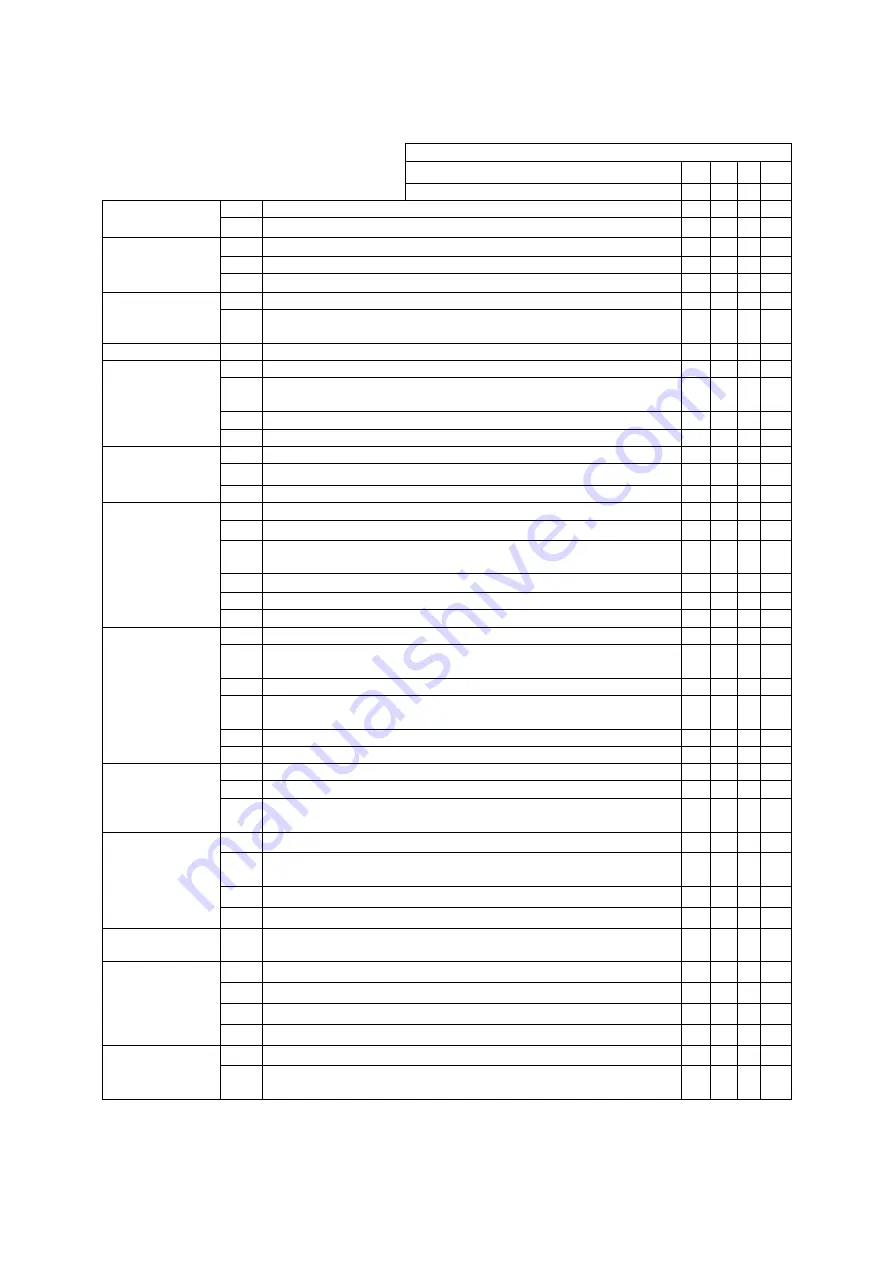

9. TROUBLE DIAGNOSTICS

9.1 MAINTENANCE LIST

Maintenance Time Interval

Standard=

●

W

M M M

Refrigerating house=

#

1

3

6 12

Chassis and

truck frame

1.1

Inspection of any damage of bearing parts

●

1.2

Inspection of all joints of bolts

●

Driving part

2.1

Inspection of noise and leakage of driving system

●

2.2

Inspection of oil level of driving system

●

2.3

Replace lubrication

#

●

Wheel part

3.1

Inspection of wearing and damage state

●

3.2

Inspection of bearings inside wheels and ensure compact fit with

wheels a)

●

Steering system

4.1

Inspection of steering operation motion

●

Braking system

5.1

Inspection of performance and adjust it

#

●

5.2

Inspection of reset function of gas spring and any leakage or

damage

●

5.3

Inspection of wearing state of brake wheel

●

5.4

Inspection of brake connection and adjust it if necessary

●

Lifting equipment

6.1

Inspection of performance, wearing and adjust it

●

6.2

Inspection by sight of any block of loading wheel

●

6.3

Inspection of any wearing or damage of edge of forks and pallet

#

●

Hydraulic system

7.1

Inspection of performance

#

●

7.2

Inspection of any leakage or damage of all joints b)

#

●

7.3

Inspection of any leakage or damage of hydraulic cylinder, safety

and reliability of attachment

#

●

7.4

Inspection of oil capacity

#

●

7.5

Replace hydraulic oil and filter d

)

#

●

7.6

Inspection of adjustment function of pressure regulator

#

●

Electrical system

8.1

Inspection of performance

●

8.2

Inspection of safety and reliability of connection of all cables, and if

any damage

●

8.3

Inspection of Amperage of fuse

8.4

Inspection of safety, reliability and function of switches and

unlocking cam equipment

●

8.5

Inspection of connector, replace the worn part if necessary

8.6

Inspection of function of alarm equipment

#

●

Motor

9.1

Inspection of wearing state of carbon brush

●

9.2

Inspection of safety of motor attachment

●

9.3

Clean motor frame with vacuum cleaner, inspection of wearing state

of commutor

#

●

Battery

10.1

Inspection of density and capacity of acid, voltage of battery

#

●

10.2

Inspection of safety device of connection terminal, applicability of

grease

#

●

10.3

Clean connector of battery, inspection of compactness of fit

#

●

10.4

Inspection of damage of battery cable, replace it if necessary

●

Lubrication

11.1

Paint grease to the truck according to the time schedule of

lubrication feeding

#

●

Integrated

measurement

12.1

Inspection of the fault in grounding of electrical system

●

12.2

Inspection of driving speed and braking distance

●

12.3

Inspection of lifting and lowering speed

●

12.4

Inspection of safety device and closing device

●

Demonstration

13.1

Commissioning under load rating

●

13.2

After above maintenance, the truck is certificated to be reliable for

operator

#

●

a

)

About 100 hours after initial operation, check if any loose nuts on wheels and tighten them if necessary.

b

)

About 100 hours after initial operation, check if any leakage of hydraulic parts and tighten them if required.

c) 500 hours after initial operation.

Summary of Contents for CG1646

Page 16: ...18 3 ELECTRIC SYSTEM 3 1 ELECTRIC DIAGRAM WIRING DIAGRAM ...

Page 19: ...21 CG1646 Universal Electric Parts List ...

Page 31: ...33 3 7 CURTIS CONTROLLER ...

Page 50: ...52 5 DRIVE WHEEL 5 1 THE DRIVE WHEEL Driving Wheel MR250FR ...

Page 64: ...66 9 2 TROUBLE SHOOT ...

Page 65: ...67 ...