7

When working with others, choose a group leader and work according to his instructions. Do not

perform any maintenance beyond the agreed work.

Unless you have special instructions to the contrary, maintenance should always be carried out with

the motor stopped. If maintenance is carried out with the motor running, there must be two men

present : one operating the stacker and the other one performing the maintenance. In such a case,

never touch any moving part.

Before making adjustment, lubricating or performing any other maintenance, shut off all power

controls.

When removing parts containing O-ring Gaskets or seal clean the mounting surface and replace

with new sealing parts.

Thoroughly clean the machine. In particular, be careful to clean the grease fittings and the area

around the dipsticks. Be careful not to let any dirt or dust into the system.

Use only approved, nonflammable cleaning solvents.

When changing the oil or fitter, check the drained oil and filter for any signs of excessive metal

particles or other foreign materials.

Always use NOBLELIFT genuine parts for replacement. ENSURE REPLACEMENT PARTS OR

COMPONENTS ARE IDENTICAL OR EQUIVALENT TO ORIGINAL PARTS OR COMPONENTS.

When checking an open gear case, there is a risk of dripping things in. Before removing the covers

to inspect such cases, empty everything from your pockets. Be particularly careful to remove

wrenches and nuts.

Do not allow anyone to stand or walk under the elevated forks or load.

Never use the forks to lift people.

Summary of Contents for CG1646

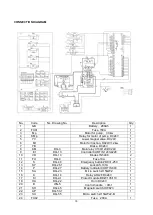

Page 16: ...18 3 ELECTRIC SYSTEM 3 1 ELECTRIC DIAGRAM WIRING DIAGRAM ...

Page 19: ...21 CG1646 Universal Electric Parts List ...

Page 31: ...33 3 7 CURTIS CONTROLLER ...

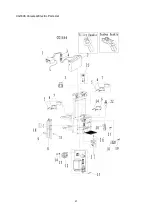

Page 50: ...52 5 DRIVE WHEEL 5 1 THE DRIVE WHEEL Driving Wheel MR250FR ...

Page 64: ...66 9 2 TROUBLE SHOOT ...

Page 65: ...67 ...