13

button is activated, the truck decelerates and/ or starts travelling into the backwards

direction (‘Bw.’) for a short distance and stops. Please consider, that this button also

operates, if the truck is not travelling and the tiller is in the operating zone.

h.

Malfunctions

If there are any malfunctions or the truck is inoperative, please stop using the truck and

activate the emergency button (3) by pushing it. If possible, park the truck on a safe

area, turn the key switch (1) anti- clockwise and remove the key.

Inform immediately the manager and, or call your service. If necessary, tow the truck

out of the operating area by using dedicated lifting equipment.

i.

Emergency

In emergencies, push the emergency button (3). All electrical functions will be stopped.

Keep safe distance.

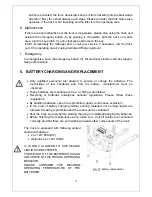

5. BATTERY CHARGING AND REPLACEMENT

Only qualified personnel are allowed to service or charge the batteries. The

instructions of this handbook and from the battery- manufacturer must be

observed.

These batteries are maintenance free; re- filling is prohibited.

Recycling of batteries undergoes national regulations. Please follow these

regulations.

By handling batteries, open fire is prohibited, gases could cause explosion!

In the area of battery charging neither burning materials nor burning liquids are

allowed. Smoking is prohibited and the area must be ventilated.

Park the truck securely before starting charging or installing/changing the batteries

Before finishing the maintenance work, make sure, that all cables are connected

correctly and that there are no disturbing towards other components of the truck.

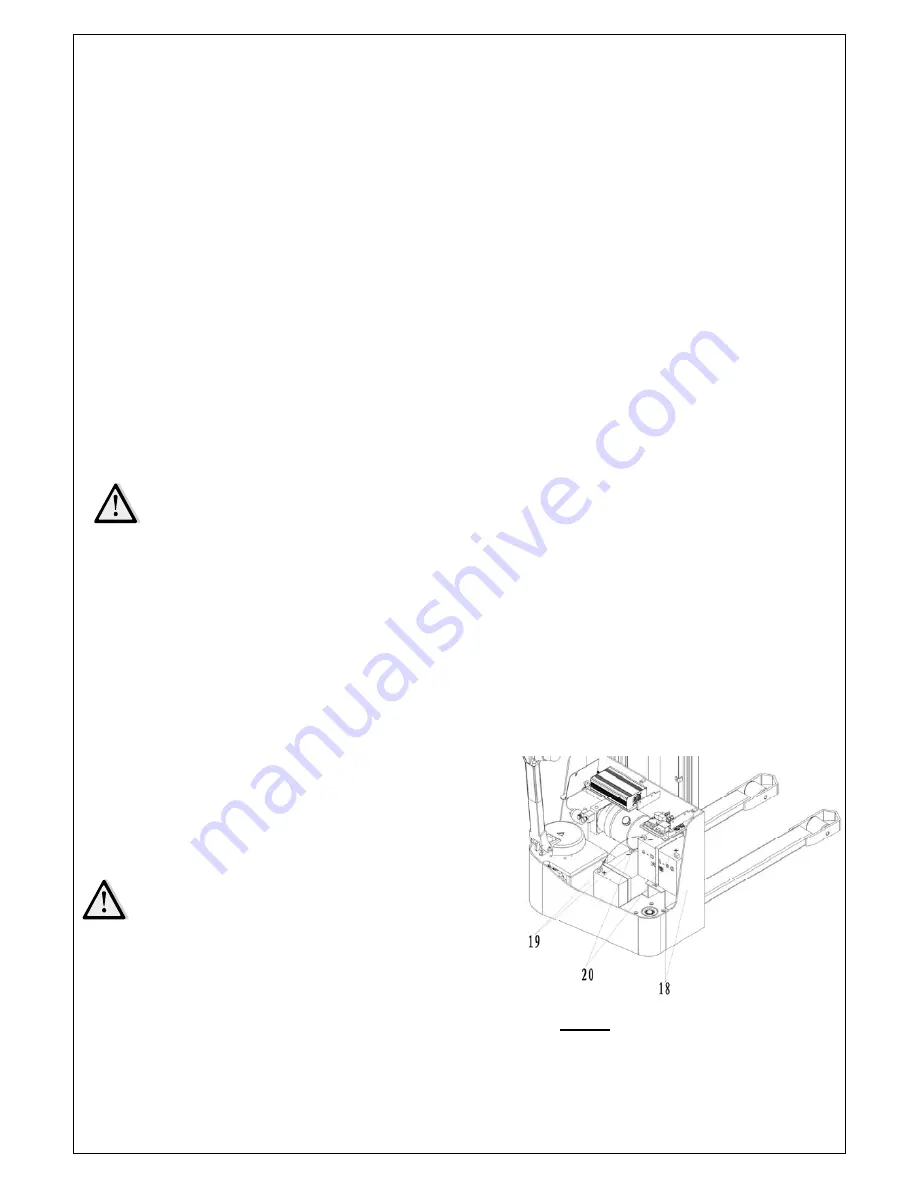

The truck is equipped with following sealed

liquid acid batteries:

2 pc 12V/ 85Ah(C5)

Optional: 2 pc 12V/ 106Ah

IT IS ONLY ALLOWED TO USE SEALED

LIQUID ACID BATTERIES.

THE WEIGHT OF THE BATTERIES HAS AN

INFLUENCE TO THE TRUCKS OPERATING

BEHAVIOR.

PLEASE CONSIDER THE MAXIMUM

OPERATING TEMPERATURE OF THE

BATTERIES.

Fig. 12: battery replacement

Summary of Contents for ECL 10

Page 28: ......

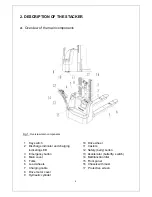

Page 31: ...3 Fig 1 Main components...

Page 36: ...8 Fig 5 Mast Assembly 5 1 Double Mast...

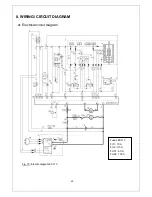

Page 38: ...10 Fig 6 Electronic control board assembly...

Page 41: ...13 Fig 8 Electric parts and components...

Page 53: ...25 Fig 14 Tiller arm assembly...

Page 55: ...27 Fig 15 Economic tiller head...

Page 60: ...32 Fig 18 Sticker for US...

Page 65: ...4 Fig 2 S ticker for US...

Page 67: ...6 Fig 3 Appearance...

Page 74: ...13 Fig 8 Mast assembly 8 1 Two stage mast...

Page 76: ...15 Fig 9 Electronic control board assembly...

Page 79: ...18 Fig 11 Electric parts and components...

Page 88: ...27 Fig 15 Driving system...

Page 91: ...30 Fig 17 T iller arm assembly...

Page 93: ...32 Fig 18 Economic tiller head...