17

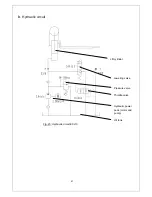

b.

Lubricating points

Lubricate the marked points according to the

maintenance checklist. The required grease

specification is: DIN 51825, standard grease.

Fig. 16: Lubricating points

c.

Check and refill hydraulic oil

The required hydraulic fluid- type is

H-LP 46, DIN 51524

Viscosity is 41.4 - 47

Depending on the type the amount

is

2,5L to 3,0L

Waste material like oil, used batteries or other

must be probably disposed and recycled according

to the national regulations and if necessary

brought to a recycling company.

d.

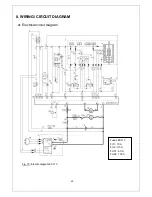

Checking electrical fuses

Remove the main cover. The fuses are located

according to fig. 20; the size is according to table 5.

Fig. 18: Location fuses

1

Bearings in wheels

2

Main frame post

3

Chain

4

Hydraulic system

5

Steering bearing

6

Gear box

Table 5: Size of the fuses

Rate

FU1 10A

FU2

FU 01

60A

FU 02

100A

Fig. 17: Oil level

Summary of Contents for ECL 10

Page 28: ......

Page 31: ...3 Fig 1 Main components...

Page 36: ...8 Fig 5 Mast Assembly 5 1 Double Mast...

Page 38: ...10 Fig 6 Electronic control board assembly...

Page 41: ...13 Fig 8 Electric parts and components...

Page 53: ...25 Fig 14 Tiller arm assembly...

Page 55: ...27 Fig 15 Economic tiller head...

Page 60: ...32 Fig 18 Sticker for US...

Page 65: ...4 Fig 2 S ticker for US...

Page 67: ...6 Fig 3 Appearance...

Page 74: ...13 Fig 8 Mast assembly 8 1 Two stage mast...

Page 76: ...15 Fig 9 Electronic control board assembly...

Page 79: ...18 Fig 11 Electric parts and components...

Page 88: ...27 Fig 15 Driving system...

Page 91: ...30 Fig 17 T iller arm assembly...

Page 93: ...32 Fig 18 Economic tiller head...