Summary of Contents for ECL 10

Page 28: ......

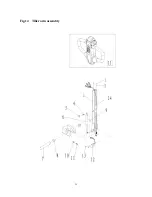

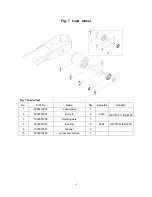

Page 31: ...3 Fig 1 Main components...

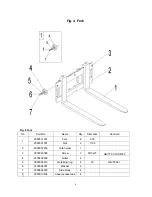

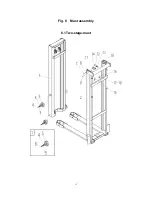

Page 36: ...8 Fig 5 Mast Assembly 5 1 Double Mast...

Page 38: ...10 Fig 6 Electronic control board assembly...

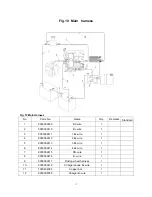

Page 41: ...13 Fig 8 Electric parts and components...

Page 53: ...25 Fig 14 Tiller arm assembly...

Page 55: ...27 Fig 15 Economic tiller head...

Page 60: ...32 Fig 18 Sticker for US...

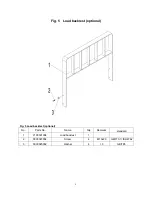

Page 65: ...4 Fig 2 S ticker for US...

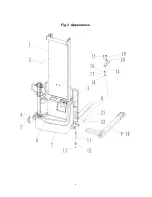

Page 67: ...6 Fig 3 Appearance...

Page 74: ...13 Fig 8 Mast assembly 8 1 Two stage mast...

Page 76: ...15 Fig 9 Electronic control board assembly...

Page 79: ...18 Fig 11 Electric parts and components...

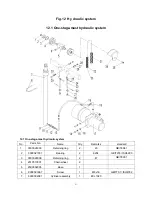

Page 88: ...27 Fig 15 Driving system...

Page 91: ...30 Fig 17 T iller arm assembly...

Page 93: ...32 Fig 18 Economic tiller head...