7

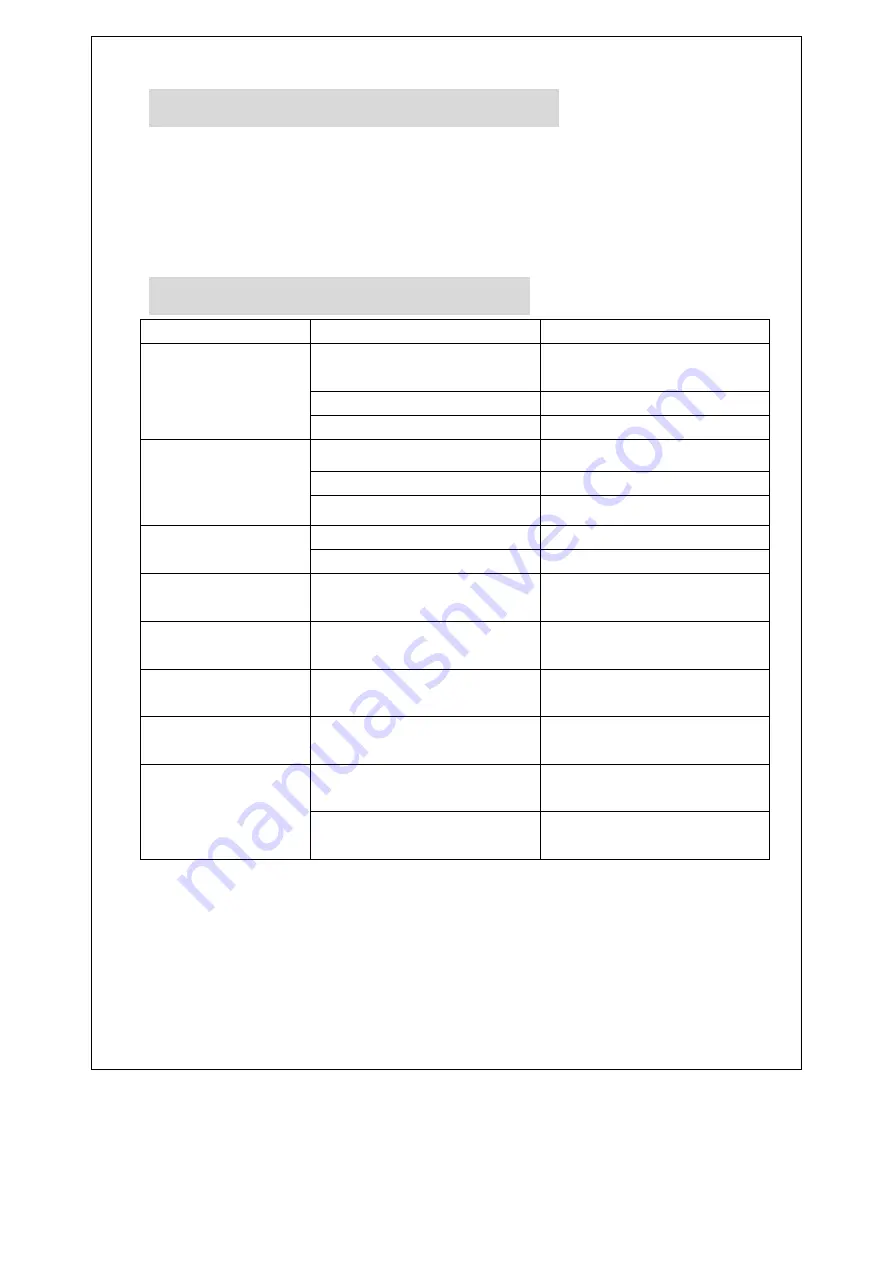

7. REGULAR INSPECTION

(

1.) Check the items emphasized in daily inspection (daily).

(2.) Lubricate with grease the rails where roller moves. Also lubricate the

grease nipples (monthly).

(3.) Lubricate all the pivoting points and axles (every 6 months).

(4.) Replace the hydranlic oil (every 12 months).

8. TROUBLE SHOOTING

TROUBLE CAUSE

REPAIR

1. Faulty wiring.

1.Check the wiring refering to the

actual wiring diagram.

2.Battery cord is disconnected. 2.Connent

the

battery cord .

Table does not rise

while motor does not

run.

3.Battery charge is insufficient.

3. Charge the battery.

1.Faulty adjustment of relief valve

1.Adjust relief valve again.

2.Faulty hydraulic pump.

2.Replace power pack.

Table does not rise

while motor runs.

3.shortage of hydraulic oil.

3.Add oil.

1.Oil leakagein lowering valve .

1.Replace lowering valve.

Vertical creep of table

2.Oil leakage from hydraulic circuit

2.Check hydraulic circuit and repair.

Oil leakage from

cylinder

Faulty sealing.

Replace sealing.

Oil leakage from

piping or joint.

Insufficient tightening.

Tighten joint again.

Oil leakage from air

breathing

Excessive quantity of oil

Reduce oil quantity.

Battery fail to be

charged

Battery is worn out

Replace battery

1.charger is not connected to

breaker.

Connect cord to breaker.

Charger shows

abnormal by red flash

2.Poles are reverse

inconnection.

Interchange the connection of

poles