16

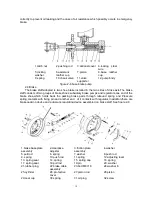

1. Wheel hub

2. Wheel fixing screw

3. Needle cage

4. Shaft seal

5. Taper Roll. Bearing

6. Set-Right Spacer

7. Spacer

8. Breather plug

9. Socket head cap screw

10. Socket head cap screw

11. Socket head cap screw

12. Housing

13. Screw Plug

14. Magnetic Screw Plug

15. Locking pin

16. Needle cage

17. Taper Roll. Bearing

18. Retaining ring

19. Ring-gear carrier disc

20. Ring gear

21. Stud

22. Washer

23. Hexnut

24. Planet carrier

25. Retaining ring

26. Planet gear

27. Roller bearing

28. Retaining ring

29. Locknut

30. Retaining ring

31. Helix gear

32. Retaining ring

33. Ball bearing

34. Cover

35. Helix pinion

36. Ball bearing

37. Retaining ring

38. Retaining ring

39. Locking pin

40. Sun pinion

41. Feather key

42. Lever

43. Elastic pin

44. Pin

45. Socket head cap screw

46. Screw Plug

47. Cover

48. Seal

49. Washer

50. Connection

51. Bleeding valve cap

52. Bleeding valve

53. Basket

54. Basket

55. Piston

56. Elastic disc

57. Disk Pusher

58. Friction disk

59. Steel disk

60. Support disk

61. Retaining ring

62. Locking pin

63. Spring

64. Stud

65. Spring

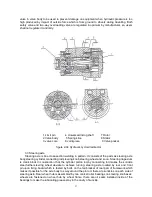

Figure 2-7 Decelerator

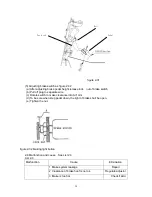

1.2.2 Care and maintenance

○

,1 Before conducting running-in test of the gear box, users shall fill in gear oil (gear oil

shall be selected in accordance with the instructions. Please refer to Table 2-1 for the specific

requirements). Fill oil into the hole at top of the axle shell until oil is spilled out of the oil level hole

in central axle.

○

,2 It is necessary to check every 2000 working hours that the stroke of the brake piston is

not over 3.5 mm, otherwise it is necessary to replace the brake disk to avoid accidents.

○

,3 Check all the fasteners each 50 working hours . If any looseness is found, tighten it

immediately.

○

,4 Check the wheel axle and wheel hub connection each 50 working hours for any oil

leakage. Re-apply sealant if any leakage is found.

○

,5Check if the oil level in the gear box meets standards. If the oil level reduces, users

should promptly fill up

○

,6 Oil in the gear box should be changed every 1000 working hours.

○

,7 Annual technical maintenance: Disassemble the drive axle for inspection every year.

○

,8Check and debug requirements during the installation process: