21

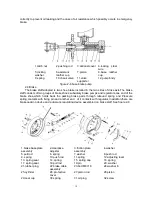

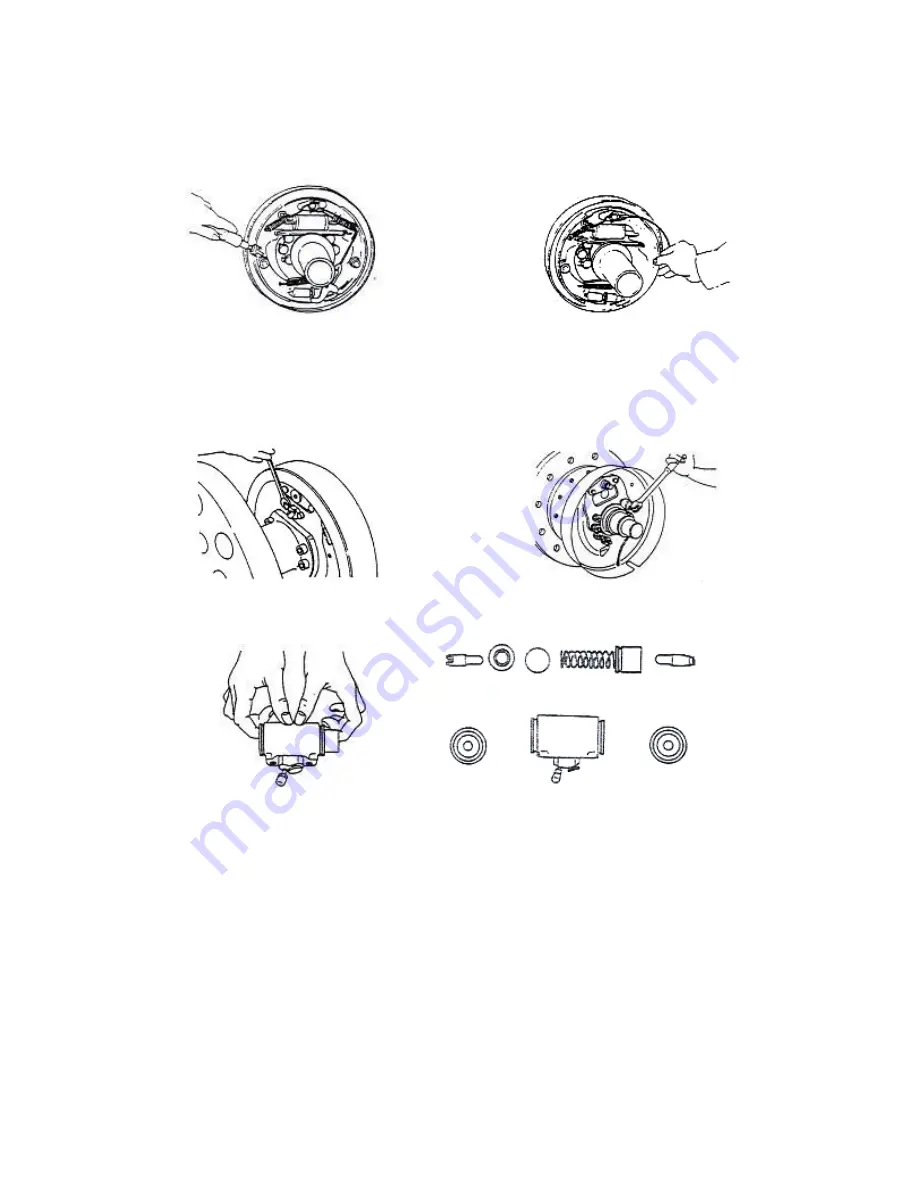

figure 2-16 figure 2-17

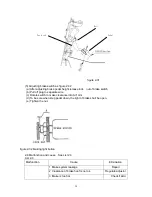

(3) Disassemble the fixed spring on leading brake shoe.See figure 2-18

(4) Disassemble the leading brake shoe and secondary brake shoe. Then disassemble the

regulator and regulating spring.See figure 2-19

figure 2-18 figure 2-19

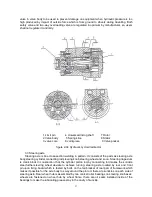

(5) Disassemble the brake tube from the driven brake pump,and disassemble the assembling

bolts on the subsidiary brake pump.Then disassemble the subsidiary brake pump from brake

device motherboard.See figure 2-20

(6) Disassemble the E baffle ring to fast the brake dragline from brake device

motherboard.Then disassemble brake device motherboard bolts,and disassemble brake device

motherboard from drive axle. See figure 2-21

figure 2-20 figure 2-21

(7) Analyze subsidiary brake pump:Disassemble scraper seal. Press one terminal piston to

push out another terminal one,then push out the rest one with finger.See figure 2-22

figure 2-22

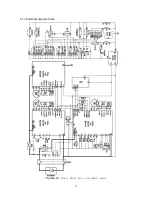

2.6.2 Brake device inspection

Inspection of parts.Repair and replacement of Damaged parts

(1) Check up if there is any rust of inner surface of sub-pump and outside of piston; then

measure the clearance between piston and pump body. Standard size: 0.03mm

—0.10mm;limit

size: 0.15mm

(2) Visually Check up if there is any damage and deformation of cup leather, please replace if

abnormal.

(3) Measure the free length of brake sub-pump, if abnormal, please replace.

(4) Measure the thickness of friction slice, if exceed the limit wear, please replace. Standard:

8.0mm;limit: 2.0mm. See figure 2-23.

(5) Eye-measure if there is any damage on inner surface of brake drum, if abnormal, amend

by lapping. If exceed amendment limit, please replace. Standard: 314mm;limit: 316mm. see figure

2-24