12

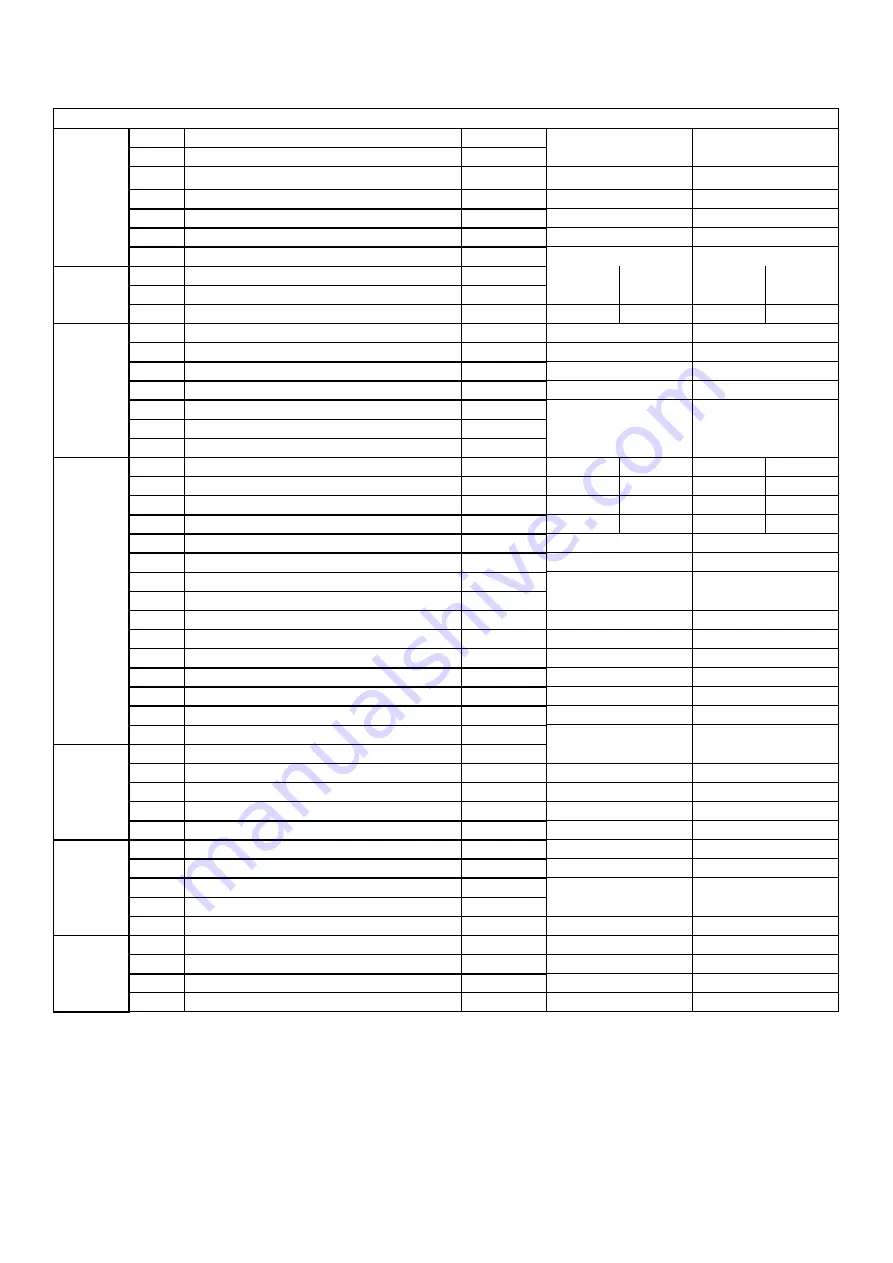

2.2 SPECIFICATION SHEETS

Type sheet for industrial truck acc. to VDI 2198

D

is

ti

ng

ui

s

hi

ng

ma

rk

1.2

Manufacturer`s type designation

PS 10M

PS 10M ST

1.3

Power (battery ,diesel, petrol, gas, manual)

Battery

Battery

1.4

Operator type

Pedestrian

Pedestrian

1.5

Load Capacity / rated load

Q(t)

1.0

1.0

1.6

Load centre distance

c(mm)

600

600

1.8

Load distance ,centre of drive axle to fork

x(mm)

782

742

1.9

Wheelbase

Y(mm)

1170

1170

W

e

ig

ht

2.1

Service weight

kg

536

566

676

706

2.2

Axle loading, laden front/rear

kg

850/680

850/710

905/765

920/780

2.3

Axle loading, unladen front/rear

kg

320/210

320/240

385/285

400/300

T

ir

es,

C

h

as

si

s

3.1

Tires

Polyurethane (PU)

Polyurethane (PU)

3.2

Tire size, front

∅

x w

∅

252×89

∅

252×89

3.3

Tire size, rear

∅

x w

∅

84×70

∅

84×70

3.4

Additional wheels(dimensions)

∅

x w

∅

100×40

∅

100×40

3.5

Wheels, number front/rear(x=driven

1x+2/2

1x+2/2

3.6

Track, front

b10mm

500

500

3.7

Track, rear

b11 (mm)

390

1000-1370

D

im

e

n

s

io

n

s

4.2

Lowered mast height

h1 (mm)

1970

2370

1970

2370

4.3

Free Lift height

h2 (mm)

1530

1930

1530

1930

4.4

Lift height

h3 (mm)

1530

1930

1530

1930

4.5

Extended mast height

h4 (mm)

1970

2370

2090

2490

4.9

Height of tiller in drive position min./ max.

h14mm

934/1205

934/1205

4.15

Height, lowered t

h13mm

85

40

4.19

Overall length

l1mm

1725

1765

4.20

Length to face of forks

l2mm

573

613

4.21

Overall width

b1mm

692

692

4.22

Fork dimensions

s/e/l (mm)

60/150/1150

35/100/1150

4.25

Distance between fork-arms

b5 (mm)

540

252/800

4.32

Ground clearance, centre of wheelbase

m2mm

25

25

4.33

Aisle width for pallets 1000X1200

Ast (mm)

2200

2297

4.34

Aisle width for pallets 800X1200

Ast (mm)

2140

2297

4.35

Turning radius

Wa (mm)

1360

1360

P

e

rf

o

rm

a

n

ce d

at

a

5.1

Travel speed, laden/ unladen

km/h

5.5/5.5

5.5/5.5

5.2

Lift speed, laden/ unladen

m/s

0.076/0.185

0.076/0.185

5.3

Lowering speed, laden/ unladen

m/s

0.105/0.110

0.105/0.110

5.8

Max. gradeability, laden/ unladen

%

5/10

5/10

5.10

Service brake

Electromagnetic

Electromagnetic

E

le

c

tr

ic

-

Mo

to

r

6.1

Drive motor rating S2 60min

kW

0.9

0.9

6.2

Lift motor rating at S3 4.5%

kW

1.2

1.2

6.3

Battery acc. to DIN 43531/35/36 A, B, C,

No

No

6.4

Battery voltage, nominal capacity K5

V/Ah

2x12 / 106

2x12 / 106

6.6

Energy consumption acc: to VDI cycle

kWh/h

0.8

0.8

A

d

d

it

io

n

a

l

d

a

ta

8.1

Type of drive control

AC- speed control

AC- speed control

8.4

sound level at driver`s ear acc. to EN 12053

dB(A)

67

67