21

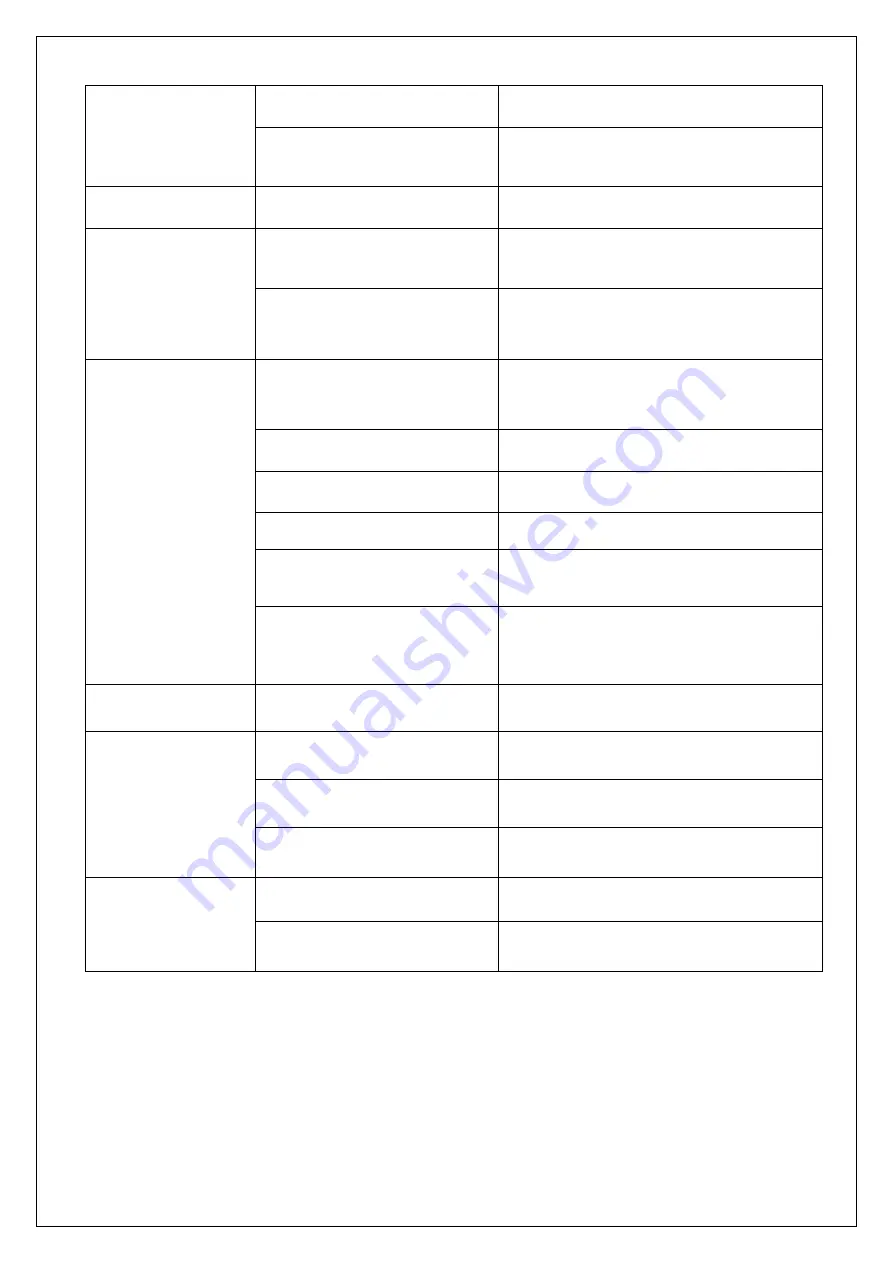

Hydraulic oil level too low

Check and refill hydraulic oil.

Oil leakage

Check and repair the seal performance of

the oil hoses and/or cylinder.

Oil suction failure

Excessive quantity of oil.

Reduce oil quantity.

Loads cannot be

lowered

Dirty oil blocks the control valve.

Check the hydraulic oil and clean the

control valve. Replace hydraulic oil if

necessary.

The lowering electromagnetic

valve is not activated or it is

damaged.

Check or replace the lowering

electromagnetic valve .

Stacker cannot be

operated

Battery is charging

Charge the battery completely and then

remove the main power plug form the

electrical socket.

Battery not connected

Connect the battery correctly.

Fuse failure

Check and eventually replace fuses.

The battery is discharged.

Charge the battery.

The truck is not powered on.

Check emergency switch, key switch and

other switches.

The sequence of operations is

wrong.

Move the tiller bar to the braking position

and put the tiller bar back to the operating

position, then operate the accelerator

Stacker only travels

in one direction

The accelerator and the

connectors are damaged.

Check the accelerator and the connectors.

Stacker travels very

slowly

The battery is discharged.

Check the battery status by the discharge

indicator.

The electromagnetic brake is

engaged.

Check the electromagnetic brake.

The relating tiller cables are

disconnected or damaged

Check the tiller cables and connectors.

Stacker starts up

suddenly

The controller is damaged.

Replace the controller.

The accelerator cannot turn

back to its neutral position.

Repair or replace the accelerator.

If the truck has malfunctions and can’t be operated out of the working zone, jack the truck up and go with

a load handler under the truck and ensure the truck safety. Then move the truck out of the aisle.