13

b.

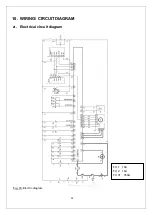

Residual lift diagram

The residual lift diagram indicates the maximum capacity Q [kg] for a given load centre c [mm] and the

corresponding lift height H [mm] for the truck with horizontal load.

The white markings on the mast indicate if the specific lifting limits reached.

For instance with a load centre of gravity distance c of 600 mm and a maximum lift height H of 1600 mm,

the max. Capacity Q is 1000 kg.

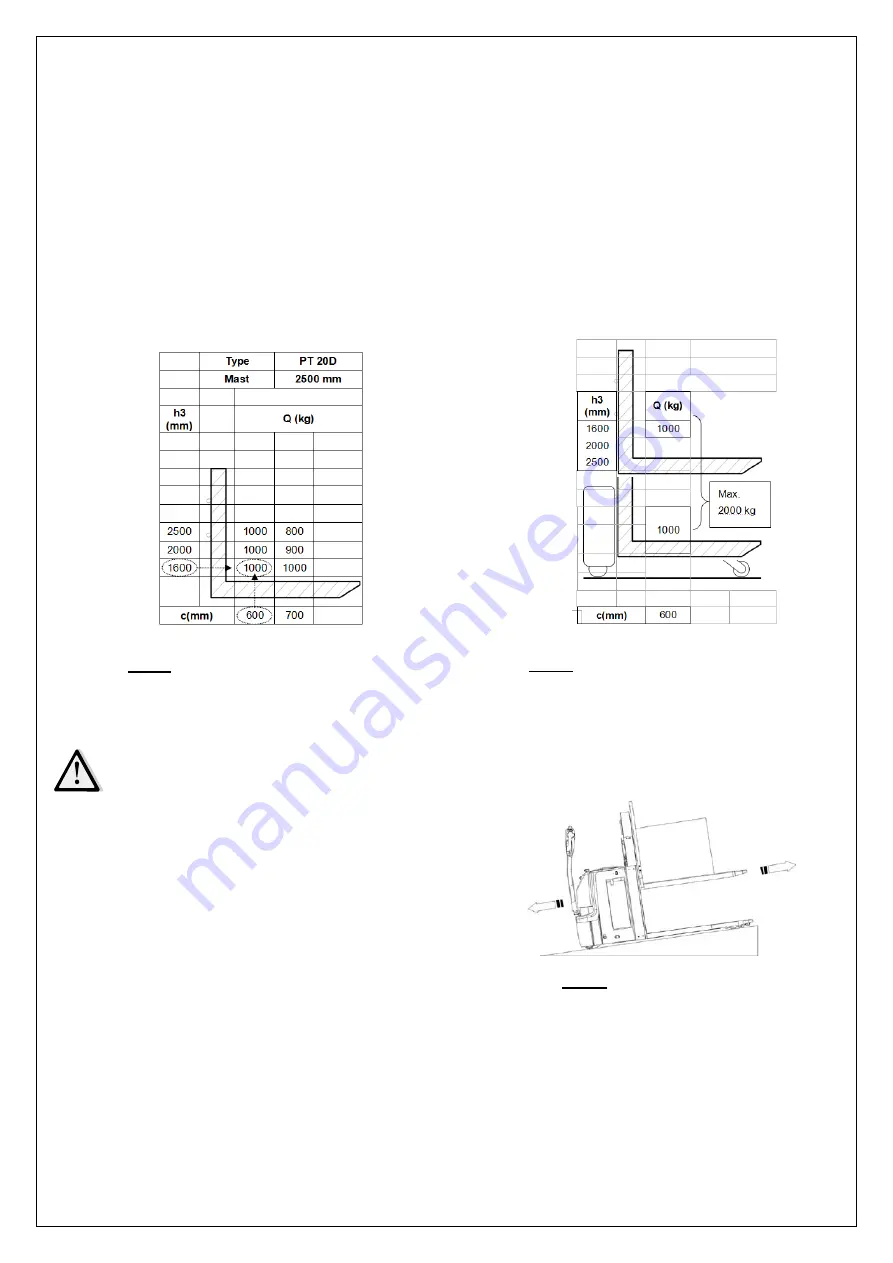

Figure 8 shows when the truck is used as pallet truck and stacker at the same time, the

load capacity of

fork and pallet is both 1000kg,

so the total

load capacity is 2000kg. When the fork lift height is within

120mm, the maximum

stack height is 1800mm.

c.

Lifting

DO NOT OVERLOAD! THE MAX. CAPACITY OF THIS TRUCK IS 2000KG

Travel with the forks lowered fully underneath the pallet until

lift the load. Press the lifting button (19) until you reach the

desired lifting height.

d.

Lowering

Press the lowering button (19) carefully.

Lower the load until the forks are near the chassis, and then

drive the truck carefully out of the load area.

Fig. 9: Load facing uphill

Fig. 7: Residual lift diagram (stacking)

Fig. 8: Residual lift diagram (double lifting)

Summary of Contents for PT 20I

Page 2: ...1...

Page 4: ...3...

Page 28: ...27 Sign not under on forks O Sign Caution charger H Warning sticker R Warning sticker Q...