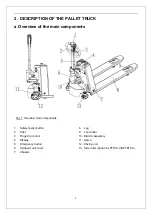

17

12

Inspect and lubricate the steering bearing if necessary

13

Inspect and lubricate the pivot points if necessary

14

Lubricate the grease nipples

Electrical system

15

Inspect the electric wiring for damage

16

Check the electric connections and terminals

17

Test the Emergency switch function

18

Check the electric drive motor for noise and damages

19

Test the display

20

Check, if correct fuses are used

21

Test the warning signal

22

Check the contactor(s)

23

Check the frame leakage (insulation test)

24

Check function and mechanical wear of the accelerator

25

Check the electrical system of the drive motor

Braking system

26

Check brake performance, if necessary replace the brake disc or adjust the air gap

Battery

27

Check the battery voltage

28

Clean and grease the terminals and check for corrosion and damage

29

Check the battery housing for damages

Charger

30

Check the main power cable for damages

31

Check the start-up protection during charging

Function

32

Check the horn function

33

Check the air gap of the electromagnetic brake

34

Test the emergency braking

35

Test the reverse and regenerative braking

36

Test the safety (belly) button function

37

Check the steering function

38

Check the lifting and lowering function

39

Check the tiller arm switch function

General

40

Check if all decals are legible and complete

41

Inspect the castors, adjust the height or replace these if worn out.

42

Carry out a test run

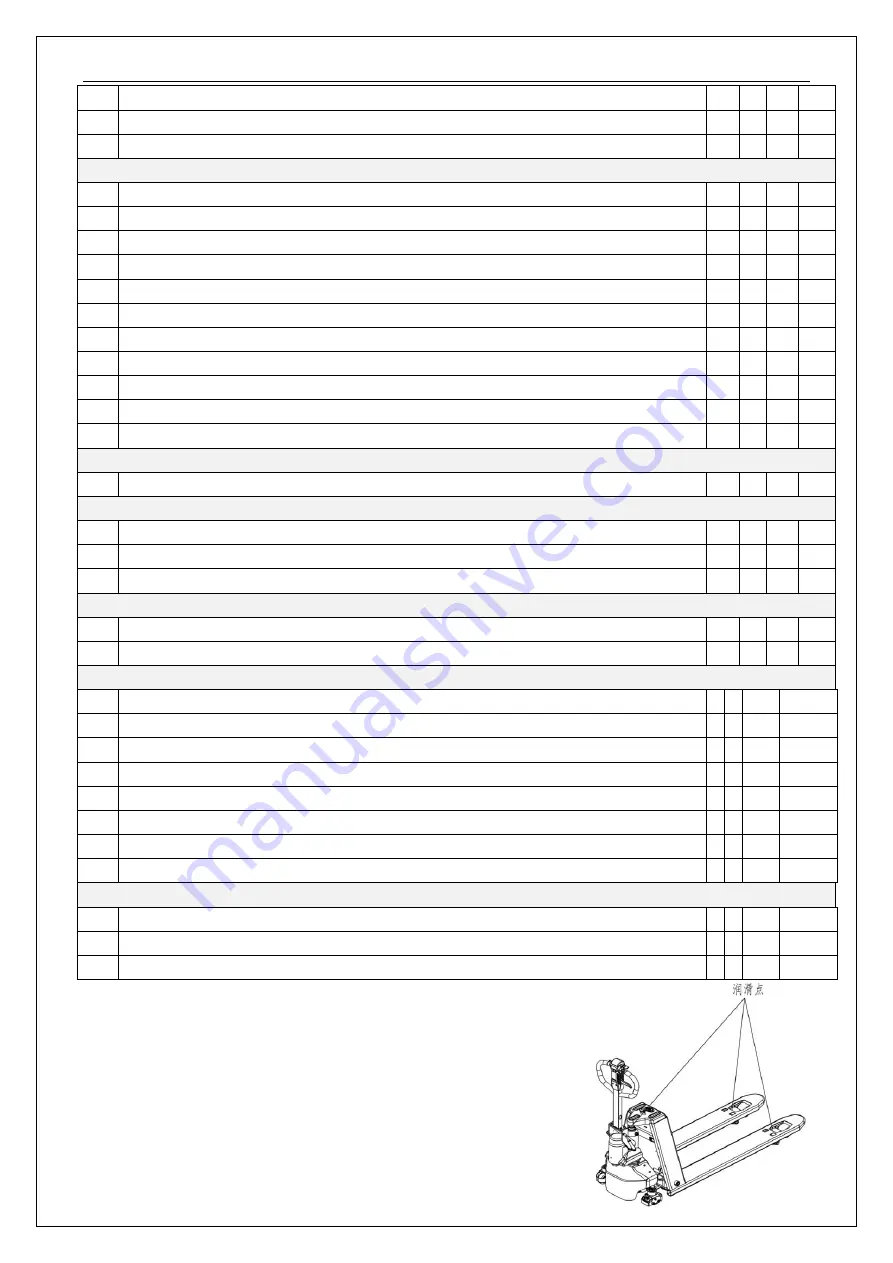

b. Lubricating points

Lubricate the marked points according to the maintenance checklist.

The required grease specification is: DIN 51825, standard grease.