26

Speed Scrub 350 9016424 (09-2017)

OPERATION

MACHINE OPERATION

FOR SAFETY: Do not operate machine, unless

operator manual is read and understood.

PRE-OPERATION CHECKLIST

Check the battery

fl

uid. Fill as necessary.

Machines with Smart-Fill Automatic Battery

Watering option: Check the automatic battery

watering tank. Fill with distilled water as

necessary.

Check the battery charge level. Charge as

necessary.

Check brushes for wear and damage. Remove

wire, string, or twine wrapped around the main

scrub brushes.

Check scrub head skirt for damage and ensure

skirt is properly positioned on scrub head.

Clean the squeegee water trap.

Check the squeegee vacuum hose for debris

or blockage.

Check the squeegees for damage and wear.

Con

fi

rm the recovery tank is drained and

cleaned.

Check the recovery tank cover seal for wear

and damage.

Clean the recovery tank debris tray.

Clean the

fl

oat shut off screen.

ec-H2O

Scrubbing: Con

fi

rm all conventional

cleaning agents/restorers are drained and

rinsed from the solution tank.

ec-H2O

Scrubbing: Con

fi

rm the solution tank

is

fi

lled with clear cool water only.

Machines with SE (Severe Environment)

option: Check detergent tank level. Fill

detergent tank as necessary.

Check steering for proper operation.

Check the horn.

Check maintenance records to determine

maintenance requirements.

OPERATING MACHINE

For control panel operating instructions, see

CONTROL PANEL OPERATION.

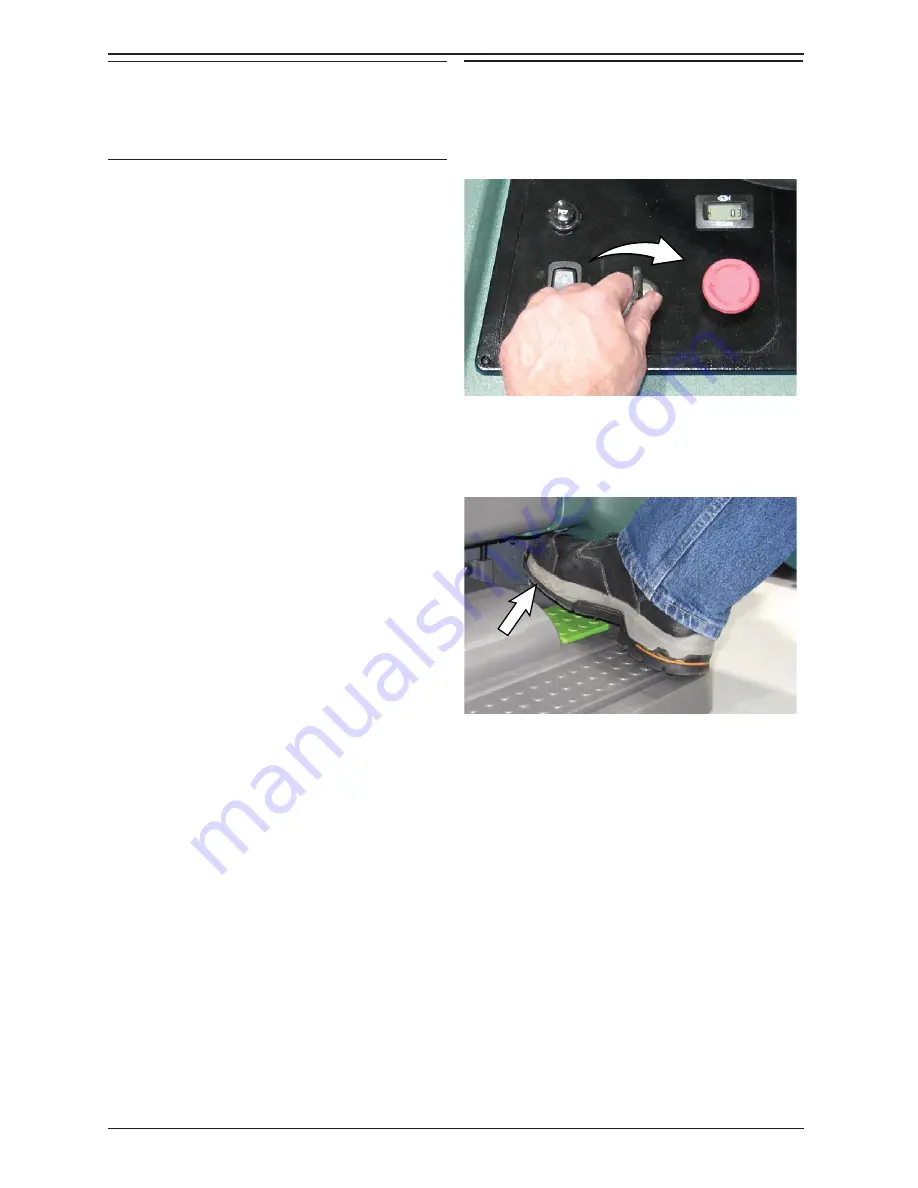

1. Turn the key switch to the ON position.

2. Position both feet on the operator platform so

the heals are pressing the operator presence

pedal. The right foot is OFF the green go

pedal.

3. ec-H2O models - The ec-H2O system will

automatically turn on at key start up. The ec-

H2O indicator will appear on the control panel

indicating that the system is activated.