Nokia Customer Care

RM-12

Issue 1 11/2004

Copyright

©

Nokia. All rights reserved

Page 80

The camera module as a component is not a repairable part i.e. components in the module

may not be changed. Cleaning dust from the front face is the only allowable operation, do this

by using clean compressed air.

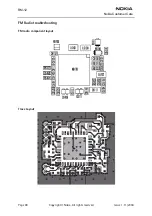

Figure Cross section of the camera module and assembly principle shows the cross section

view of the camera module. The main parts of the module are

•

Lens unit including lens aperture

•

Infrared filter, which is used to prevent infrared light from contaminating

the image colors. IR filter is glued to the EMI shielded camera body

•

Camera body, which is made of conductive metallized plastic and

attached to PWB by glue

•

Sensor array including DSP functions is glued and wire bonded to PWB

•

PWB, FR-4 type

•

Socket type connecting is used

•

Laser marked serial numbering on PWB is used for versioning

•

Passive components

•

Camera protection window is part of phone cover mechanics

•

Dust gasket between lens unit and camera protection window

Image quality analysis

Possible faults in image quality

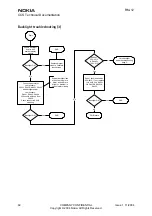

When checking for possible errors in camera functionality, knowing what error is suspected will

significantly help the testing by narrowing down the amount of test cases. The following types

of image quality problems may be expected to appear

•

Dust (black spots)

•

Lack of sharpness

•

Bit errors

In addition, there are many other kinds of possibilities for getting bad image quality, but those

are ruled out from the scope of this document since probability of their appearance is going to

be minimized by production testing.

Testing for dust

For detecting this kind of problems, take an image of uniform white surface and analyze it in

full resolution. Good quality PC monitor is preferred for analysis. Search carefully since finding

these defects is not always easy. Figure Effects of dust on optical path is an example of image

containing easily detectable dust problems.