Making the correct choice of installation is essential to ensuring adequate safety and good protection against atmospheric

agents. Remember that the control unit contains powered parts and electronic components which by their very nature are

sensitive to infi ltrations and moisture. The control unit is supplied in a container which guarantees an IP55 protection rating

if adequately installed. Install the control unit on a permanent surface that is perfectly fl at, adequately protected against

impacts and at least 40 cm off the ground.

The cables must enter the control unit from the bottom only; we recommend using wire leads and water-tight connections.

When using tubing that could fi ll up with water or if the tubing comes from an underground well, the wires must enter a

first shunting box placed at the same height as the control unit and then, from there, the wires must be passed into the

container holding the control unit, again entering from the bottom. This prevents any evaporation of the water in the tubing

from forming condensation inside the control unit itself.

1.4 Preliminary checks

1 Introduction

START-S5PV

Technical manual

-4-

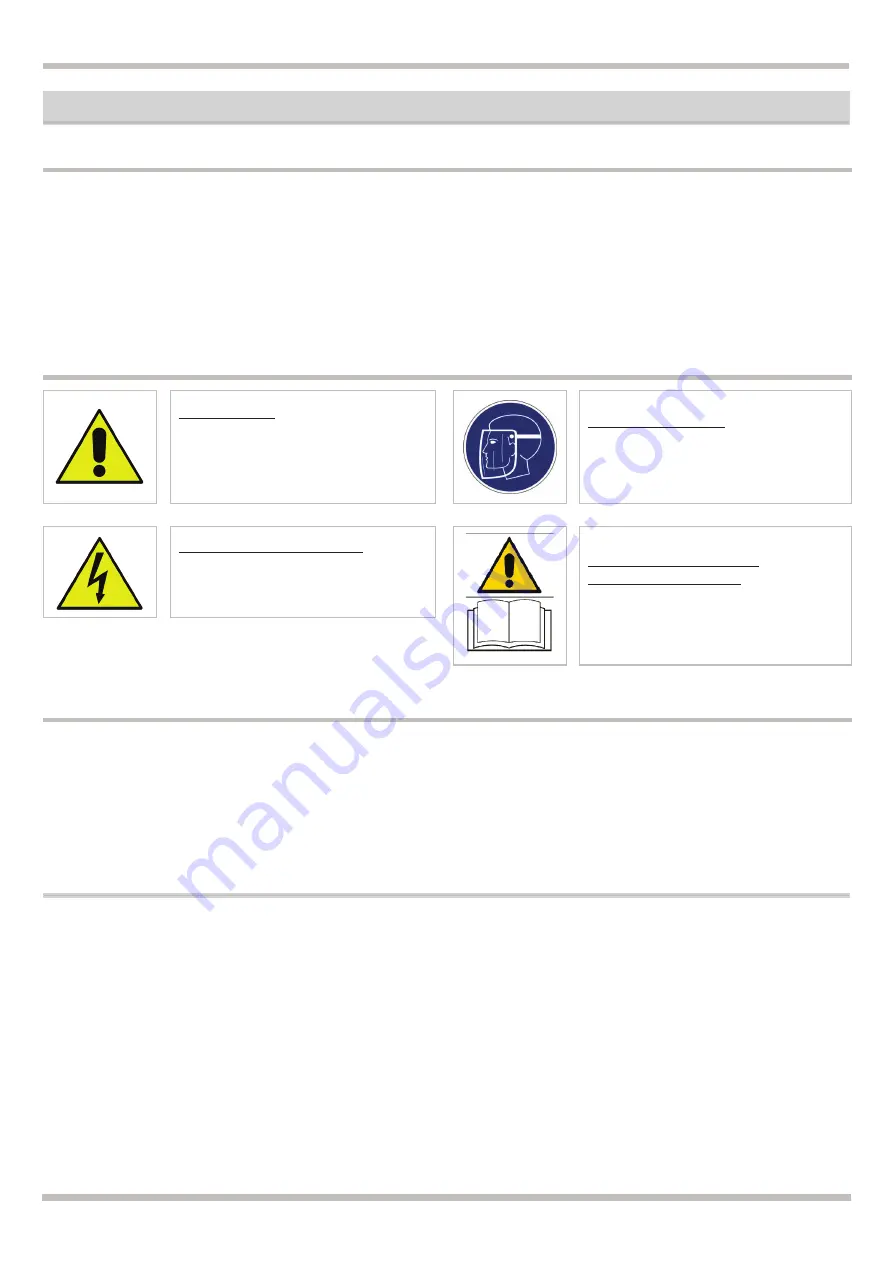

DANGEROUS

This is a warning and if it is not

respec it can provoque material dam-

age

DEVICE UNDER TENSION

The installation should be done only

from professional installer

Using the unit improperly and performing repairs or modifications personally will void the warranty. The producer declines

any responsibility for damages due to inappropriate use of the product and due to any use other than the use the product

was designed for. The producer declines any responsibility for consequential damages except civil liability for the products.

Remember that systems for automatic gates and doors must be installed by highly qualifi ed technicians only and in full

compliance with current law. Before starting installation, check that the mechanical consistency and sturdiness of the gate

or door, check that the mechanical stops are suitable to stop the movement of the gate or door even if the electrical limit

switches should fail or during manual operations.

1.1 Safety precautions

HEALTH DAMAGES

For safety reasons, protect your face

during the connection

READ CAREFULLY THE

OPERATING MANUAL

Read carefully this manul before in-

stallation and keep it for the future

1.2 Symbols and warning

1.3 Security system

These two simple diagrams show only one of the possible applications for this control unit. The risks inherent to the

“MACHINE” and the user’s requirements must be analyzed in depth in order to establish how many elements need to be

installed.

For a sure installation we suggest to install a STOP SWITCH, when it is working it stops immediatelly the door. The

SWITCH should have a normally closed contact and it opens when it is working (see Par. 3.10)