www.norco.com

16

4. Tech

It’s important to your safety, performance and enjoyment to understand how

things work on your bicycle. We urge you to ask your dealer how to do the things

described in this section before you attempt them yourself, and that you have

your dealer check your work before you ride the bike. If you have even the

slightest doubt as to whether you understand something in this section of the

Manual, talk to your dealer.

A. Wheels

NOTE : If you have a mountain bike equipped

with through-axle front or rear wheels, make sure

that your dealer has given you the manufacturer’s

instructions, and follow those when installing or

removing a through-axle wheel. If you don’t know

what a through-axle is, ask your dealer.

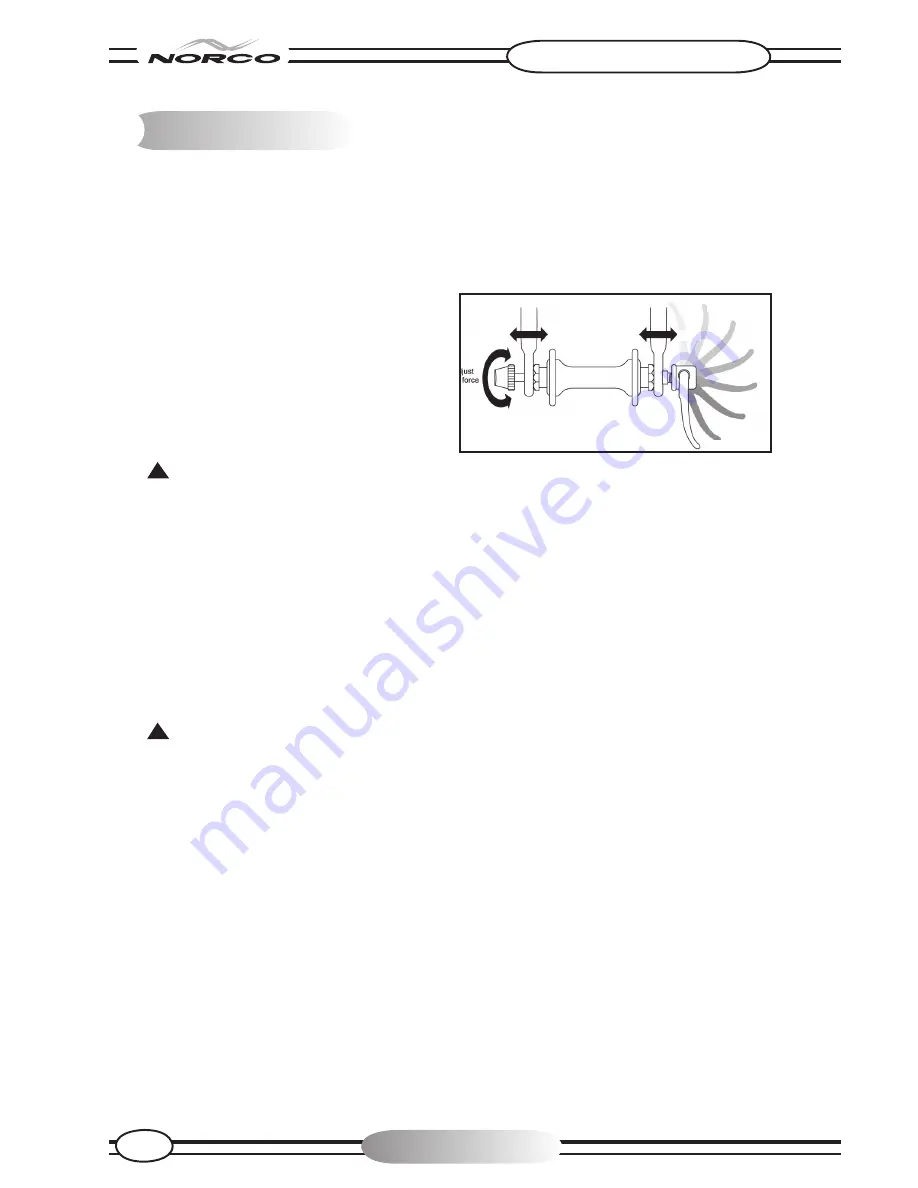

1. Wheel Quick Release

WARNING: Riding with an improperly adjusted wheel quick release

can allow the wheel to wobble or disengage from the bicycle, causing

serious injury or death to the rider. Therefore, it is essential that you:

1. Ask your dealer to help you make sure you know how to install and remove

your wheels safely.

2. Understand and apply the correct technique for clamping your wheel in place

with a quick release.

3. Each time, before you ride the bike, check that the wheel is securely

clamped.

The wheel quick release uses a cam action to clamp the bike’s wheel in place

(see fig. 6). Because of its adjustable nature, it is critical that you understand how

it works, how to use it properly, and how much force you need to apply to secure

the wheel.

WARNING: The full force of the cam action is needed to clamp the wheel securely. Holding the nut

with one hand and turning the lever like a wing nut with the other hand until everything is as tight as you

can get it will not clamp the wheel safely in the dropouts.

a. Adjusting the quick release mechanism

The wheel hub is clamped in place by the force of the quick release cam

pushing against one dropout and pulling the tension adjusting nut, by way of the

skewer, against the other dropout. The amount of clamping force is controlled by

the tension adjusting nut. Turning the tension adjusting nut clockwise while

keeping the cam lever from rotating increases clamping force; turning it

counterclockwise while keeping the cam lever from rotating reduces clamping

force. Less than half a turn of the tension adjusting nut can make the difference

between safe clamping force and unsafe clamping force.

b

.

Front Wheel Secondary Retention Devices

Most bicycles have front forks which utilize a secondary wheel retention device

to keep the wheel from disengaging if the quick release is incorrectly adjusted.

Secondary retention devices are not a substitute for correct quick release

adjustment.

Fig 6

open

closed

closed

open

turn to

adjust

clamping

force

closed position

open position

4. Tech

Summary of Contents for multi-speed bicycles

Page 1: ...for multi speed bicycles 7th Edition www norco com ...

Page 2: ......