SK 500E – Brief instructions for frequency inverters

4

BU 0540 EN-1516

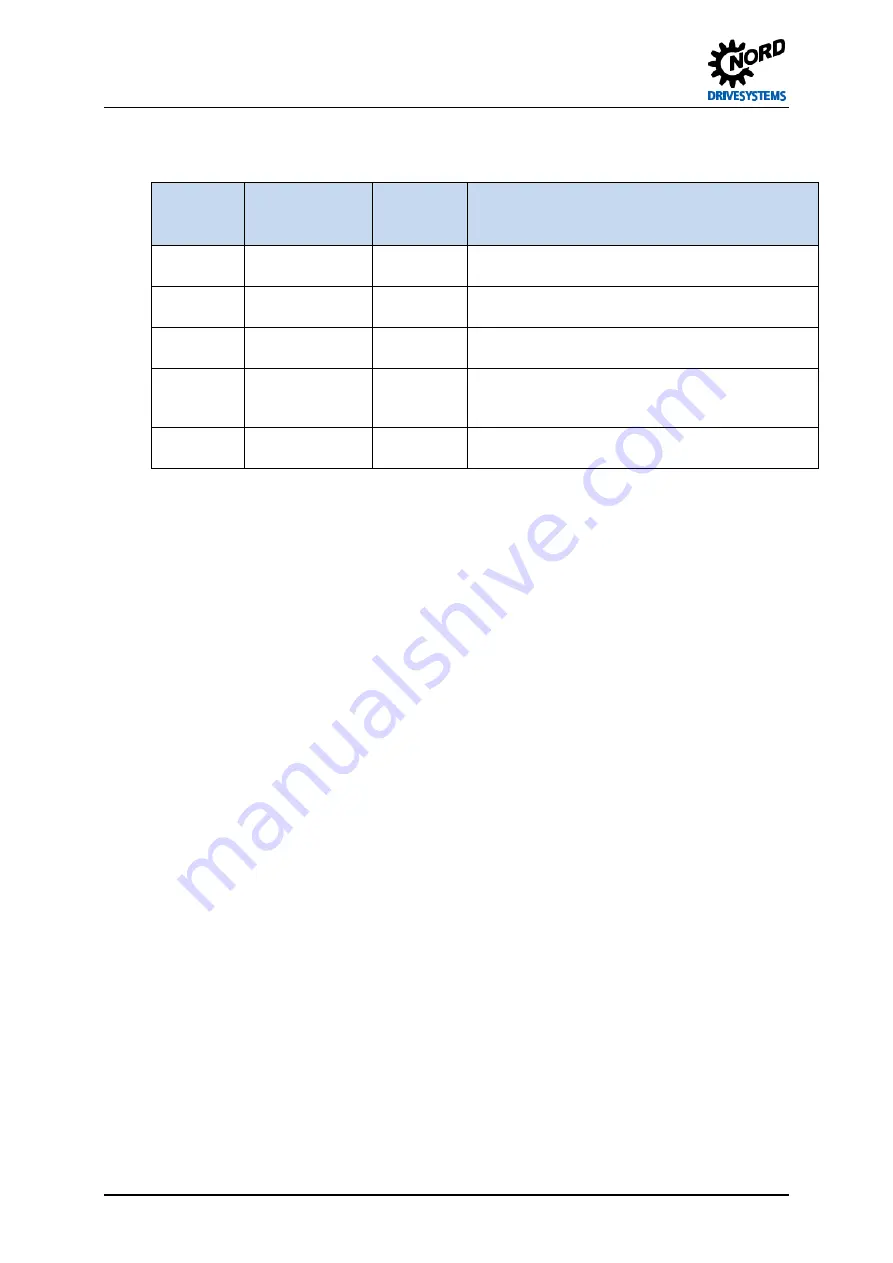

Version list

Title,

Date

Order number

Device

software

version

Remarks

BU 0540,

July 2006

6075402 / 2006

V 1.1 R1

First issue, based on BU 0500 GB (March 2005)

BU 0540,

June 2012

6075402 / 3811

V 2.0 R0

based on BU 0500 DE (Part No.: 6075001/3811)

BU 0540,

March 2013

6075402 / 1013

V 2.0 R5

based on BU 0500 DE (Part No.: 6075001/1013)

BU 0540,

February

2015

6075402 / 0715

V 3.0 R1

based on BU 0500 DE (Part No.: 6075001/0715)

BU 0540,

April 2016

6075402 / 1516

V 3.1 R0

based on BU 0500 DE (Part No.: 6075001/1516)

Table 1: Version List BU0540

Pos: 7 /Anl eitung en/El ektr oni k/FU und Starter/0. Pr olog/Gültig keit [Kurzanlei tungen] @ 1\mod_1340632846633_388.docx @ 28140 @ @ 1

G

Validity

The following brief instructions are based on the main instructions (see version list) of the

relevant inverter series, which is also definitive for commissioning. These brief instructions

summarise the information which is required for the basic commissioning of a standard drive

technology application. Detailed information, especially with regard to parameters, options and

special functions can be obtained from the latest versions of the main instructions for the

frequency inverter as well as any supplementary instructions for field bus options (e.g.

PROFIBUS DP) or inverter functionalities (e.g.: PLC).

Pos: 8 /Allgemei n/Allgemei ngültige Modul e/Ur heberrechtsver mer k @ 5\mod_1410955083459_388.docx @ 150427 @ @ 1

Copyright notice

As an integral component of the device described here, this document must be provided to all

users in a suitable form.

Any editing or amendment or other utilisation of the document is prohibited.

Pos: 9 /Allgemei n/Allgemei ngültige Modul e/H erausgeber @ 0\mod_1325779078002_388.docx @ 5270 @ @ 1

Publisher

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Straße 1 • 22941 Bargteheide, Germany • http://www.nord.com/

Fon +49 (0) 45 32 / 289-0 • Fax +49 (0) 45 32 / 289-2253