60

LIBERO LINE FRY TOP INDUCTION

5

TROUBLESHOOTING

The following chapters are intended only for authorized technicians / engineers

5.1 INTRODUCTION

Refer to the alarms described at §

6

SERVICING

THE

APPLIANCE

The following chapters are intended only for authorized technicians / engineers

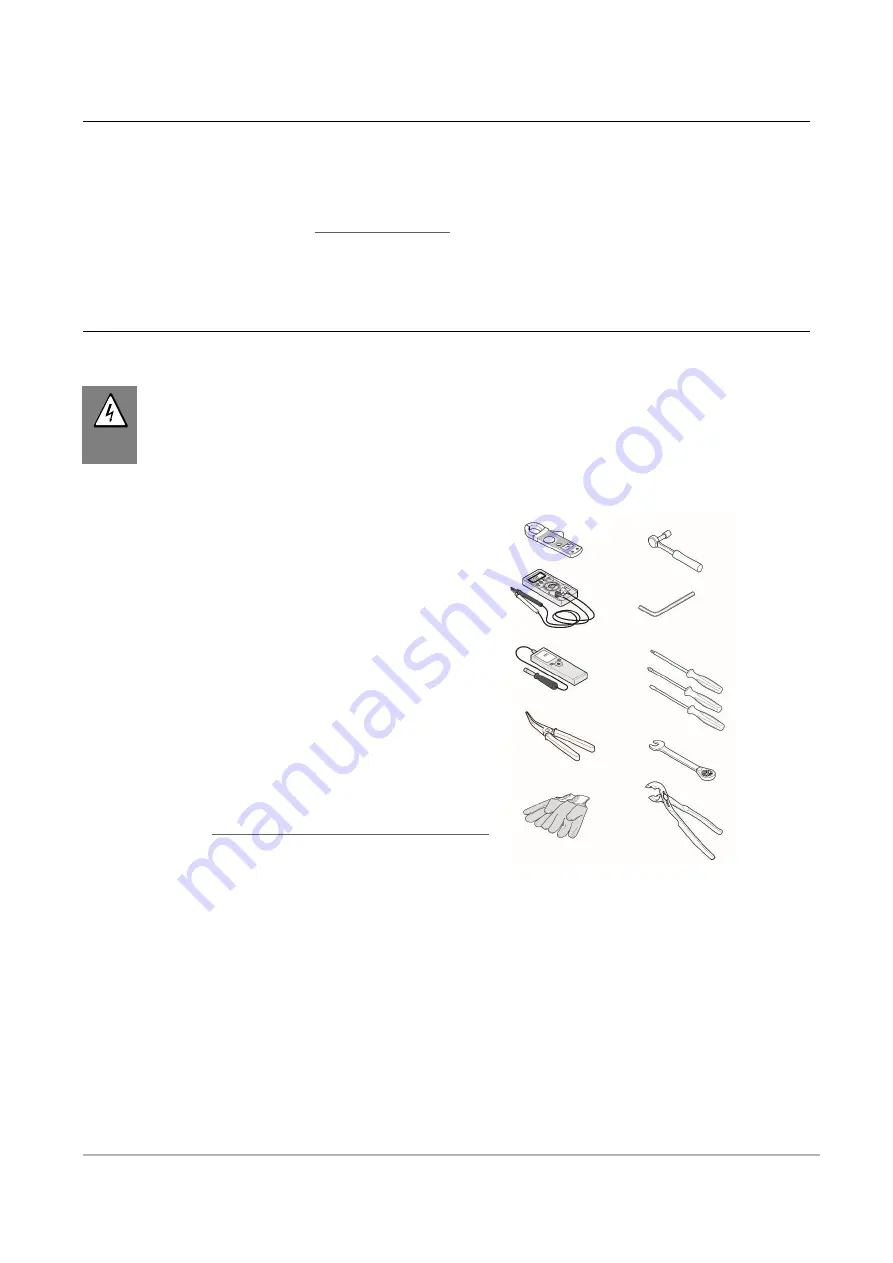

6.1 LIST OF NEEDED TOOLS

Complete Socket & Wrench set (from 6 to 24)

Complete allen button set

Bent long nose pliers

Screwdrivers Philips "small / medium / large"

Screwdrivers flat "small / medium / large"

Clamp amp meter

Multimeter (voltage reader)

Tongue groove pliers (water & gas pipes)

Grip lock plier

Protective gloves (heatproof / cut proof)

WARNING !

Take GREAT CARE when connecting / testing anything with live current, if you are unsure what you are

doing and how to use your equipment safely, then

DON'T DO IT.

Summary of Contents for 406600899

Page 1: ...Service Manual Fry Induction Top IGEC 3P 2ZQT Art 406600899 2021 04 ...

Page 13: ...13 LIBERO LINE FRY TOP INDUCTION DOUBLE ZONE ...

Page 21: ...21 LIBERO LINE FRY TOP INDUCTION In case of need the supply cable can be replaced removed ...

Page 44: ...44 LIBERO LINE FRY TOP INDUCTION ...

Page 45: ...45 LIBERO LINE FRY TOP INDUCTION ...

Page 47: ...47 LIBERO LINE FRY TOP INDUCTION ...

Page 48: ...48 LIBERO LINE FRY TOP INDUCTION ...

Page 50: ...50 LIBERO LINE FRY TOP INDUCTION ...

Page 51: ...51 LIBERO LINE FRY TOP INDUCTION ...

Page 54: ...54 LIBERO LINE FRY TOP INDUCTION ...