SAFETY

BC 60 "Trailblazer" Brushcutter

Section 1-6

OCT/2012 (49458202)

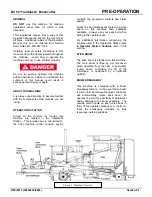

LOCKOUT-TAGOUT PROCEDURES

NORDCO has provided the means to lockout this machine. NORDCO cannot be held

responsible for injury caused by failure to comply with your company’s

Lockout/Tagout

Procedures

.

The following procedures are designed to lead the operator through the steps required to shut the machine

down and prepare it for performing mechanical maintenance work. These procedures are intended to release

potentially dangerous stored energy forms and make the machine safe to begin repairs. It is your company’s

responsibility to

Lockout/Tagout Procedures

based on this list, train you in their proper and safe use, and to

periodically inspect your work area to verify that you are complying with the procedures.

Lockout/Tagout

Procedures must be followed!

SAFETY PROCEDURES

LOCKOUT/TAGOUT

1. Apply the Electrical Interlock/Warmup.

2. Chock wheels to prevent accidental rolling of machine on grade.

3. If you have not already done so, determine which components are to

have maintenance. Place all machine mechanical systems or workheads

in the full up and locked positions.

4. When mechanical locking up of equipment is not feasible for

maintenance lower the component to the ground prior to working on the

equipment.

5. Turn the

ignition switch

to the

OFF

position. This turns off the power to

the control circuits on the machine. Place a

TAGOUT card

in close

proximity to the ignition switch.

6. Turn the

battery disconnect switch

(BDS)

to the

OFF

position.

a. For machines with the BDS on the left side of the center (front)

control console: Place a

TAGOUT card

on the switch after you

have switched it to the OFF position.

b. For machines with a remotely located BDS (usually next to the

battery box itself): Close the cover to the disconnect switch and

place a

LOCKOUT lock

on the box after you have switched it to

the OFF position.

7. Bleed off hydraulic pressure by slowly cracking hose fitting (1/8-1/4 of

turn CCW) at the cylinder/motor/pump of the hydraulic circuit being

worked on. Service or perform maintenance on circuit after the steady

flow of oil is gone.

8. Follow all of your company’s lockout/tagout rules before proceeding.

Note: When working on machine components, be aware that moving

components during repairs may create energy (ie., moving a hydraulic

cylinder). Proper precautions should be taken.

Summary of Contents for Trailblazer BC60

Page 2: ......

Page 48: ...BC 60 Trailblazer Brushcutter MAINTENANCE AUGUST 2012 49458202 8203 Section 3 3...

Page 49: ...MAINTENANCE BC 60 Trailblazer Brushcutter Section 3 4 AUGUST 2012 49458202 8203...

Page 64: ...BC 60 Trailblazer Brushcutter MAINTENANCE MARCH 2011 49458201 Section 3 21 TORQUE REQUIREMENTS...