STELLA

1192000 Rev.03 – EN

31

11. LIGHTING

IMPORTANT: The first time that the appliance is lit, there will be an odour given off (due to the drying of

the adhesives of the junction chord), which disappears after a short use. It must be

ensured, in any case, a good ventilation of the environment. Upon the first ignition we

suggest loading a reduced quantity of fuel and slightly increasing the calorific value of the

equipment.

To perform a correct first lighting of the products treated with paints for high temperature, it is necessary to

know the following information:

•

the construction materials of the involved products are not homogeneous, as matter of fact there

are simultaneously parts in cast iron, steel, refractory material and majolica;

•

the temperature to which the body of the product is subject is not homogeneous: from area to area,

variable temperatures within the range of 300°C - 5 00 °C are detected;

•

during its life, the product is subject to alternated lighting and extinguishing cycles in the same day,

as well as to cycles of intense use or of absolute standstill when season changes;

•

the new appliance, before being considered seasoned has to be subject to many start cycles to

allow all materials and paints to complete the various elastic stresses;

•

in detail, initially it is possible to remark the emission of smells typical of metals subject to great

thermal stress, as well as of wet paint. This paint, although during the manufacture it is backed at

250 °C for some hours, must exceed many times and f or a given period of time the temperature of

350 °C before becoming completely embedded in the m etallic surfaces.

Therefore, it is extremely relevant to take these easy steps during the lighting:

1) Make sure that a strong air change is assured in the room where the appliance is installed.

2) During the first starts, do not load excessively the combustion chamber (about half the quantity

indicated in the instructions manual) and keep the product continuously ON for at least 6-10 hours

with the registers less open than the value indicated in the instructions manual.

3) Repeat this operation for at least 4-5 or more times, according to your possibilities.

4) Then load more and more fuel (following in any case the provisions contained in the installation

booklet concerning maximum load) and, if possible, keep the lighting periods long avoiding, at least

in this initial phase, short ON/OFF cycles.

5) During the first starts, no object should be leaned on the appliance and in detail on

enamelled surfaces. Enamelled surfaces must not be touched during heating.

6)

Once the «break-in» has been completed, it is possible to use the product as the motor of a car,

avoiding abrupt heating with excessive loads.

To light the fire, it is suggested to use small wood pieces together with paper or other traded lighting

means.

It is forbidden to use any liquid substance as for ex. alcohol, gasoline, oil and similar.

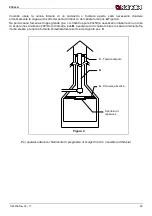

The openings for air (primary and secondary) must be opened simultaneously, just a little (also open the

eventual butterfly valve placed on the smokes exhaust pipe).

When wood starts to burn, it is possible to feed it again, close the primary air and control the combustion

through the secondary air register according to the provisions of paragraph 12.

Please always be present during this phase.

Never overload the appliance (see the technical table - max. quantity of fuel that can be loaded) .

Too much fuel and too much air for combustion can cause overheating and therefore damage the

stove.

12. NORMAL OPERATION

For safety reasons the door of the appliances with constructive system 1, must be opened only for the

loading of the fuel or for removing the ashes, while during the operation and the rest, the door of the hearth

must remain closed.

The appliances with constructive system 2 must be connected to their own flue. The operating with open

door is allowed under supervision.

IMPORTANT: For safety reasons the door of the hearth can be opened only for the loading of the

fuel. The hearth door must always remain closed during operation or rest.

The nominal power of the appliance is of kW 10. This power will be reached with a minimum depression in

the chimney of 10 Pascal (=1.0 mm of water column).