SUPER MAX - SUPER JUNIOR

18

7191051 – EN

•

not be throttled and show a vertical arrangement with deviations not greater than 45°;

•

if already used, it must be clean;

•

observe the technical data of the instructions manual;

Should the flues have a square or rectangular section, internal edges

must be rounded with a radius not lower than 20 mm. For the

rectangular section, the maximum ratio between the sides must be

≤

1.5.

A too small section causes a decrease of the draught. It is suggested a

minimum height of 4 m.

The following features are forbidden and therefore they endanger the

good operation of the appliance: asbestos cement, galvanized steel,

rough and porous internal surfaces. Picture 3 gives some examples of

execution.

The minimum section must be 4 dm

2

(for example 20 x 20 cm’s) for

appliances whose duct diameter is lower than 200 mm, or 6.25 dm

2

(for example 25 x 25 cm’s) for appliances with diameter greater

than 200 mm.

The draught created by the flue must be sufficient, but not

excessive.

A too big flue section can feature a too big volume to be heated and

consequently cause difficulties in the operation of the appliance; to

avoid this, tube the flue along its whole height. A too small section

causes a decrease of the draught.

The flue must be properly spaced from any flammable materials or

fuels through a proper insulation or an air cavity.

It is forbidden to let plant piping or air feeding channels pass in the

same flue. Moreover, it is forbidden to create movable or fixed openings

on the same for the connection of further other appliances.

5.1. CHIMNEY CAP

The draught of the flue depends also on the suitability of the chimney cap.

Therefore, if it is handicraft constructed, the output section must be more than twice as big as the internal section of

the flue.

Should it be necessary to exceed the ridge of the roof, the chimney cap must assure the discharge also in case of

windy weather (Picture 4).

The chimney cap must meet the following requirements:

•

have internal section equivalent to that of the stack.

•

have a useful output section twice as big as the flue internal one.

•

be manufactured in such a way as to prevent the penetration of rain, snow, and any other foreign body in the

flue.

•

be easily checkable, for any possible maintenance and cleaning operation.

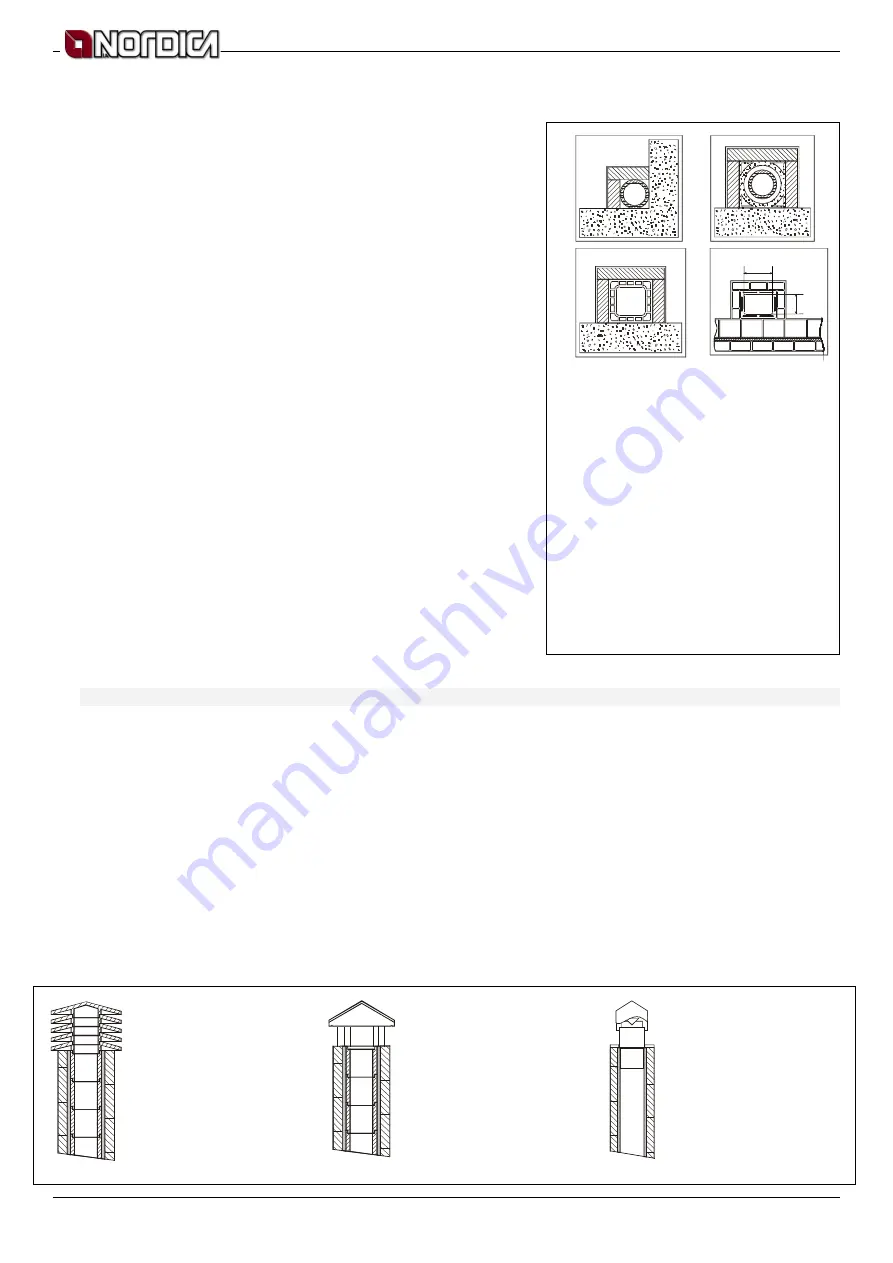

Picture 3

Picture 4

(1) AISI 316 steel flue with double

chamber insulated with material

resistant to 400°C.

Efficiency

100% excellent.

(2) Refractory flue with insulated

double chamber and external

coating in lightweight concrete.

Efficiency 100% excellent.

(3) Traditional clay flue showing a

square section with cavities.

Efficiency 80% excellent.

(4) Avoid flues with rectangular internal

section whose ratio differs from the

drawing.

Efficiency 40% poor

.

A+1/2A

A

Max.

A+1/2A

(3)

(1)

(2)

(4)

(1) Comignolo industriale

ad elementi prefabbricati,

consente

un

ottimo

smaltimento dei fumi.

(2) Comignolo artigianale.

La giusta sezione di uscita

deve essere minimo 2 volte

la sezione interna della

canna fumaria, ideale 2,5

volte.

(3) Comignolo per canna

fumaria in acciaio con

cono interno deflettore

dei fumi.