Troubleshooting

6-8

E

1996 Nordson Corporation

All rights reserved

107 041A

Issued 1/96

Manual 12-28

Problem

Possible Cause

Corrective Action

2. Conveyor moves at full

speed regardless of the

setpoint

Open cable 2455

NOTE: The

OPERATOR SCREEN and

SET-UP SCREEN menus display 000 in

actual column regardless of set point

value.

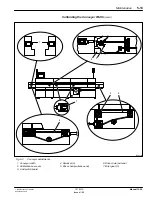

See Figure 6-2. Turn oven off and use

an ohmmeter to check cable 2455 for

an open:

230PL–1 pin A7 to 241PL–1 pin 8

230PL–1 pin A8 to 241PL–1 pin 6

230PL–1 pin A9 to 241PL–1 pin 9

If an open is found, repair cable

Bad dual-motor controller card or

conveyor speed motor assembly

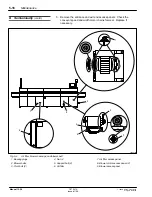

Turn on oven. Verify that +18 VDC

exists between A9 (gnd) and A8 (pos)

on the dual-motor controller card. If

voltage is not present, replace

dual-motor controller card.

If voltage is present, manually turn input

shaft of conveyor speed motor. Use a

voltmeter to verify that a toggling voltage

of 0 VDC to +5 VDC is present between

A9 (gnd) and A7 (pos) on the dual motor

controller card.

NOTE: To use an oscilloscope to verify

this toggling voltage, place the scope

ground at pin A9 and the probe at

pin A7. Access the

Raise Cover menu

and set conveyor speed to 50.8 cm/min.

Frequency of square wave will increase

until the motor speed stabilizes.

If voltage level toggles, replace dual

motor controller card. If voltage level

remain steady, replace conveyor speed

motor assembly.

Conveyor Speed Control

Problems

(contd)

Summary of Contents for 107 041A

Page 1: ...Select Cure 100 Inch IR Oven Part 107 041A NORDSON CORPORATION D AMHERST OHIO D USA ...

Page 9: ...E 1995 Nordson Corporation All rights reserved Issued 11 95 12 28s1 Section 1 Safety ...

Page 10: ...Safety 1 0 E 1995 Nordson Corporation All rights reserved Issued 11 95 12 28s1 ...

Page 148: ...Parts 7 0 E 1996 Nordson Corporation All rights reserved 107 041A Issued 1 96 Manual 12 28 ...