23

☎

IMPORTANT

Regardless of the fluid viscosity, using the correct EFD piston will give you better results.

White SmoothFlow

™

piston for most fluids, blue LV Barrier

™

for watery-thin fluids and

orange flat wall piston for thick, stringy fluids. See pages 24 - 25 for a complete description

of how EFD pistons work and the benefits they can bring to your operation.

Open

Closed

If you choose

not

to use the piston, please follow these instructions

carefully:

1.

While holding the barrel upright in one hand, twist on an orange

tip cap. Using the small funnel, fill about 2/3 full with your fluid.

2.

Open the safety clip and attach the barrel to the 10cc adapter.

3.

Close the safety clip as tight as possible.

4.

Increase vacuum by turning vacuum control knob counter-

clockwise and set to 1.5 on the vacuum pressure gauge.

5.

Then, without tipping the barrel upside down, remove the tip

cap and attach the 25 gage (red) tip.

6.

Open the safety clip. Your material may begin to bubble.

Reduce vacuum by turning vacuum control knob clockwise.

7.

If a drop begins to form at the end of the tip, slowly turn the

vacuum control knob counterclockwise to stop the drop from

growing. Wipe the tip and adjust vacuum as necessary.

Now the fluid is in proper balance. It does not bubble or drip.

Repeat tests as before, keeping the air pressure low and adjust-

ing the time for different deposit sizes. Contact EFD if you have

any questions.

US & Canada, call 800-556-3484

.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

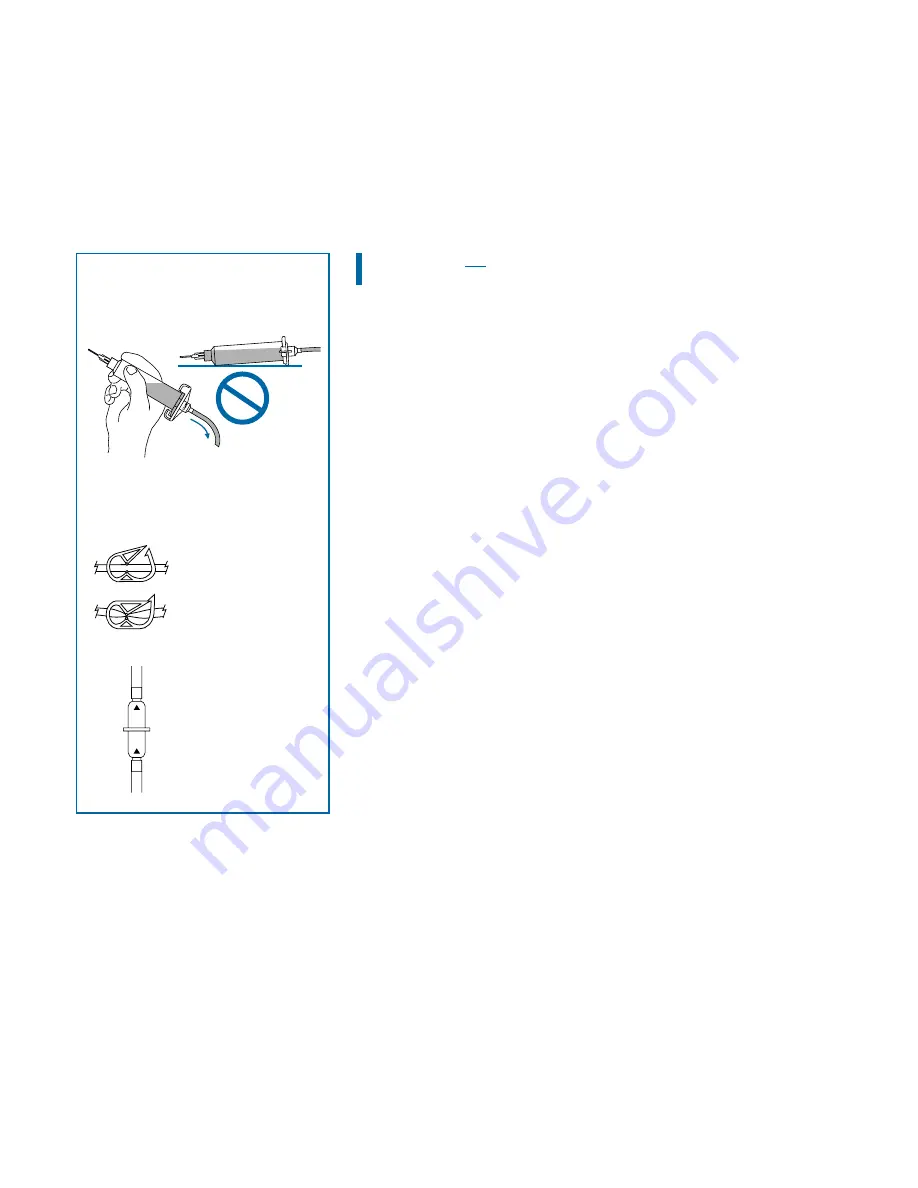

Do not tip the barrel upside down

or lay flat. This will cause the

liquid to run into the dispenser.

When changing tips

or attaching a tip cap,

snap the safety clip

completely closed to

prevent any dripping

or bubbling.

Three things to remember

If you do not use the piston

when dispensing thin fluids:

Use an EFD filter trap

(#1000FLT-Y). This

filter trap will impede

the flow should the

low viscosity liquid be

sucked back towards

the dispenser.